Imishini Yokusika I-Laser Engabizi Ngayo Yonke Isabelomali

Umshini wokusika i-laser iyithuluzi lokusika elizenzakalelayo elisebenzisa ikhithi yesilawuli se-DSP noma i-CNC ngokuhlangana nesoftware ye-CAM ukuyala CO2 noma i-FIBER laser beam ukuze unqamule izinsimbi, i-metalloids kanye ne-nonmetals emigwaqweni yamathuluzi edalwe isofthiwe ye-CAD, kanye nokusika izimo zangokwezifiso, amakhonsathi, nezimbobo ziphuma emashidini, amashubhu namaphrofayili ukuze udale izingxenye ezinembayo, izimpawu, omaka, imihlobiso, ubuciko, imisebenzi yezandla, izipho, ubucwebe, izibani namaphazili kokubili kokuzilibazisa nokusetshenziswa kwezimboni. Ekhaya, ngaphandle, ezitolo, emahhovisi, ezitudiyo, ezindaweni zokusebenzela noma ezitshalweni zokukhiqiza, ungathola amaphrojekthi esikwe nge-laser yonke indawo empilweni yakho. Kusukela ezincwadini zokukhangisa kuye kuzimpawu zomgwaqo, kusukela kwezobuciko kuye emisebenzini yobuciko, kusuka emihlobiso kuye kwezimpahla zokugqoka, ukusuka ekugcinweni kuya emaphaketheni, kusukela 3D amaphazili kuya ezingxenyeni ezizenzakalelayo, ukusuka ku-plywood kuye ku-acrylic, ukusuka ethusi kuye kweyensimbi engagqwali, ukusuka ekusikeni onqenqemeni okuqondile kuye kuye kuye kwagobile, ukusuka kuma-bevel kuye kuma-chamfers, kusuka kumashidi e-2D ukuya kumapayipi anomumo okhethekile, kanye nemifanekiso yangokwezifiso nemiklamo yomuntu siqu, abasiki be-laser bangakwazi ukuphatha cishe yonke into kalula. Ukudala ama-wood cuts omuntu siqu ngokuthengekayo CO2 i-laser cutter iphupho ngalinye le-DIYer. Ukubumba izingxenye zensimbi ezinembayo ngomshini wokusika we-CNC fibre laser othomathikhi yilokho okufunwa yiwo wonke umkhiqizi wezimboni. Nokho, ungawuthola kanjani umshini wakho we-laser kalula? Uma ungumuntu we-laser onolwazi, ungathenga zonke izingxenye ezidingekayo kanye nezinsiza ukuze uzakhele wena. Uma umusha ku-laser, ungathenga ikhithi ye-laser ehlanganiswe ngaphambilini (entsha noma esetshenzisiwe) ukuze uqale ukusika ngokushesha, futhi ungajabulela ukwanelisa okusheshayo kokudlala nge-prebuild. Ngakho-ke, ungathenga kuphi umsiki we-laser ongcono kakhulu ukufanisa izidingo zakho nesabelomali? Ungabe usabheka okunye, nansi indawo elungile yokuthenga phezulu komugqa kubo bobabili abaqalayo nabachwepheshe ngokufanayo. Ngo STYLECNC, ungathola imishini ehlukahlukene yokusika i-laser ethandwa kakhulu yaso sonke isabelomali nesidingo, kusukela kubasiki bezinga lokungena kuya ezintweni zokusika ezichwepheshile, izinhlobo zokuzilibazisa kuya ezinhlotsheni zezimboni, amamodeli okusetshenziswa kwasekhaya kuya kumamodeli okuhweba, izibhamu eziphathwayo zokusika i-laser kuya ezinhlelweni zokusika ze-CNC ezizenzakalelayo, amatafula okusika i-laser flatbed kuya 3D amarobhothi okusika i-laser, amathuluzi okusika aphathekayo emishinini yokusika laser ye-gantry ye-CNC, amandla aphansi ukuya kumandla aphakathi nendawo kanye nezinketho zamandla aphezulu. Noma ngabe usika isikhumba esithambile nendwangu, noma insimbi engagqwali eqinile, kukhona okuthile kwawo wonke umuntu. Ngaphezu kwalokho, yonke i-laser isebenziseka kalula futhi kulula ukuyisebenzisa, zonke izinketho zisezingeni eliphezulu futhi zivumelana nesabelomali somnikazi webhizinisi elincane nomakhi wezimboni, vele uqhathanise izici nezindleko, futhi uthenge kalula lokho okudingayo.

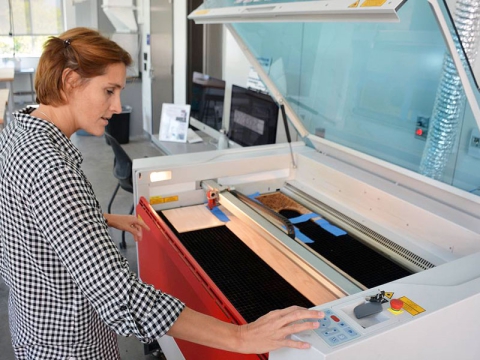

A CO2 i-laser cutter iyikhithi yamathuluzi yokuqopha nokusika okuzenzakalelayo esebenza nesilawuli se-CNC noma se-DSP ukuze ishayele ishubhu lelaser yegesi ye-carbon dioxide ukuze ikhiphe i-laser beam engu-1064μm yokunamathisela nokusika izinto ezingezona ezensimbi nama-metalloids. CO2 ama-laser angakwazi ukusingatha ukusikeka okunembayo kusuka ezindwangu ezithambile kuye kumapulasitiki aqinile, ukusuka ezinhlamvini ze-acrylic ezilula kuye eziyinkimbinkimbi 3D amaphazili okhuni, kanye nokuqoshwa okuhle engilazini, ikristalu, itshe nezitsha zobumba. Isebenziseka kalula, kulula ukuyisebenzisa futhi ihambisana nemvelo yenza kube uzakwethu ohamba phambili empilweni nasemsebenzini. Kungakhathaliseki ukuthi umusha kuma-lasers noma uchwepheshe onolwazi, uzothola okufanayo okuhle kakhulu STYLECNC. Amamodeli athandwa kakhulu nezinhlobo ze CO2 ama-laser atholakala lapha, kusukela emandleni aphansi kuye emandleni aphezulu, izinga lokungena kuye kochwepheshe, umsebenzi wokuzilibazisa ukuya ezimbonini, ikhaya kuye kwezohwebo, amakhithi amancane okusika ahlangene kuya kosayizi ogcwele. 4x8 ukusika amatafula. Izintengo ezithengekayo zisukela kokuphansi njenge $2,800 kuya phezulu $20,000 ukufanisa nanoma yisiphi isabelomali.

2025 Khipha ku-internet CO2 I-Laser Cutter Yamabhizinisi Amancane Nokusetshenziswa Kwasekhaya

Isigaba sokuqala CO2 I-Hobby Laser Cutter Machine yabaqalayo

100W Laser Wood Cutter Engraving Machine for Woodworking

2025 Umshini Wokusika I-Acrylic Laser Ongcono Kakhulu Othengiswayo

2025 Umshini Wokusika Indwangu Yezimboni Ongcono Kakhulu Othengiswayo

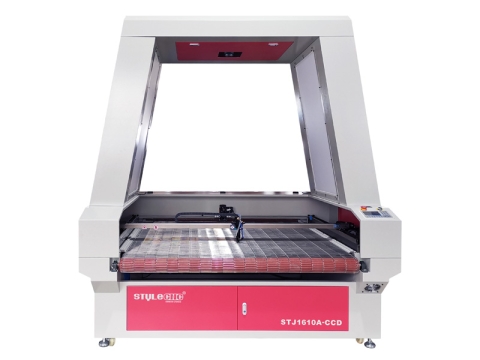

I-CNC Laser Cutter With CCD I-Visual Recognition System yekhamera

Ikhanda Elikabili CO2 I-Laser Cutter yephepha nekhadibhodi

2025 Ukuthengisa Okuhle Kakhulu 4x8 I-Laser Cutter ye-Plywood & MDF

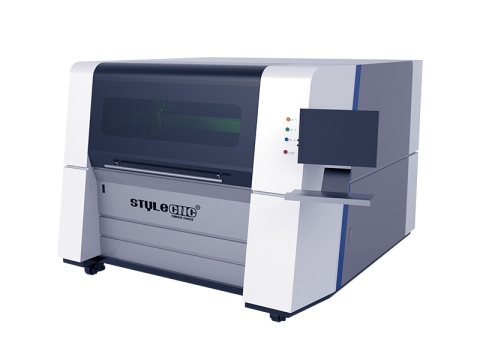

Umshini Wokusika Ibhajethi Encane Yedeskithophu Ye-Laser Engraver

2025 Umshini Ongcono Kakhulu Wokusika I-Laser Foam Wezimboni Othengiswayo

Engazinzi 4x8 Umshini Wokusika Isikhumba We-Laser Uyathengiswa

I-Fabric Laser Cutter yezingubo zezemidlalo zokuphrinta i-Sublimation

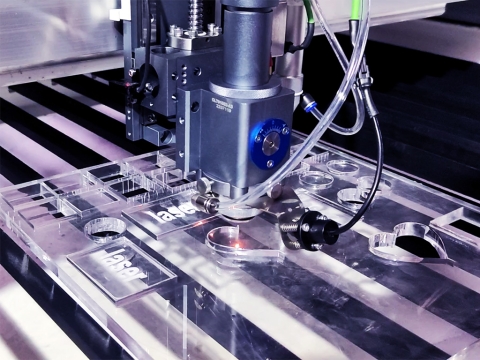

Umshini wokusika i-fiber laser uwumshini wokusika insimbi ozenzakalelayo esebenzisa isilawuli se-CNC esine-software ye-CAM ukuqondisa a 1064nm ugongolo lwe-laser ukusika ubujamo namakhonsathi emashidini ensimbi, amashubhu, imigoqo kanye namapheshana ngokuya ngamafayela esakhiwo aklanywe isofthiwe ye-CAD ukuze aqedele amaphrojekthi okwenziwa kwensimbi. Kuyithuluzi lokusika elinembayo lakho kokubili izinsimbi zeshidi namashubhu, kanye namaphrofayili ensimbi ayisicaba kanye nama-beveled. Ngengalo yerobhothi, eyenziwe yaba ngeyakho 3D ukusikeka kwensimbi kudalwe kalula. Ukusika okungathinteki ngeke kulimaze i-substrate ngethonya elincane elishisayo lendawo yokushiswa kwemisebe. Ama-laser e-fiber ayakwazi ukusika izinsimbi zibe mncane njengo-1 mm nogqinsi njengo-200 mm, namandla asukela ku- 1,500W kuya 60,000W, kanye nesivinini esiphezulu esingaphezu kwamamitha angu-120 ngomzuzu. Ama-fiber lasers angakwazi ukuphatha yonke into kusukela ezinsimbini eziqinile (njengensimbi engagqwali, insimbi emnene, i-carbon steel, i-spring steel, i-silicon steel, i-titanium, i-nickel, i-chromium, i-molybdenum, insimbi ne-alloy) kuya ezinsimbi ezicwebezelayo (njenge-aluminium, igolide, isiliva, ithusi nethusi), ezizenza zidume ngokusetshenziswa ekhaya nasekuthengiseni.

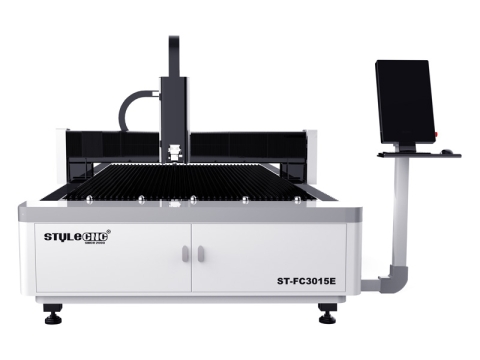

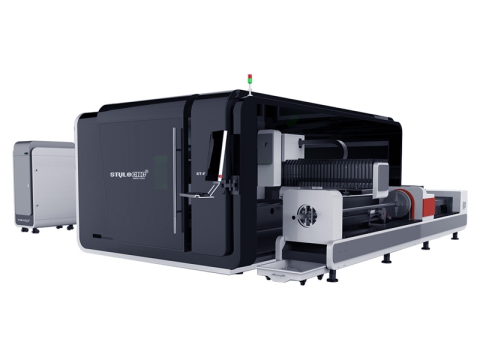

2026 I-Best Sheet Metal Laser Cutter Iyathengiswa (1500W - 6000W)

3-In-1 Handheld Laser Welding, Cleaning, Cutting Machine

2026 Umshini Wokusika I-Fiber Laser Okalwe Kakhulu Othengiswayo - 2000W

I-Mini Laser Metal Jewelry Cutter yesiliva, igolide, ithusi

2025 Umshini Wokusika I-Fiber Laser Tube Okalwe Kakhulu Othengiswayo

Speed High 12KW IPG Fiber Laser Cutter for Sheet Metal

2025 Eshibhile 4x8 I-Fiber Laser Stainless Steel Cutter 1500W

Amandla Aphezulu 6000W I-Fiber Laser Metal Cutting Machine Iyathengiswa

Industrial 3D I-Robotic Fiber Laser Cutting Machine Yensimbi

I-Entry Level Small Metal Laser Cutter yabaqalayo

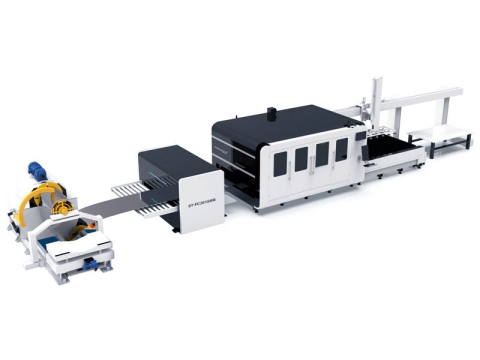

Inhloso Ekabili 6KW I-Fiber Laser Cutter ye-Metal Sheet & Tube

5x10 I-Fiber Laser Cutter enekhava Evalwe Ngokugcwele Yensimbi

I-Ultra-Large Fiber Laser Sheet Metal Cutting Table 30000W

I-Automatic Coil Fed Laser Blanking Line & Cutting System

20000W I-Ultra High Power Fiber Laser Metal Cutter Iyathengiswa

5x10 I-Industrial Fiber Laser Metal Cutting Machine Iyathengiswa

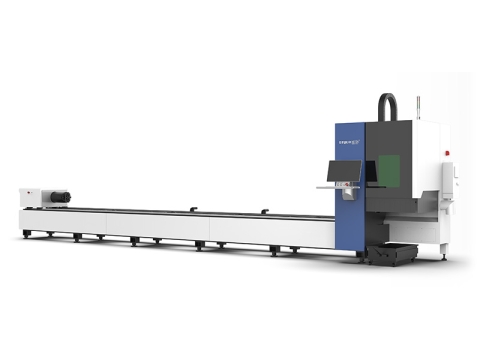

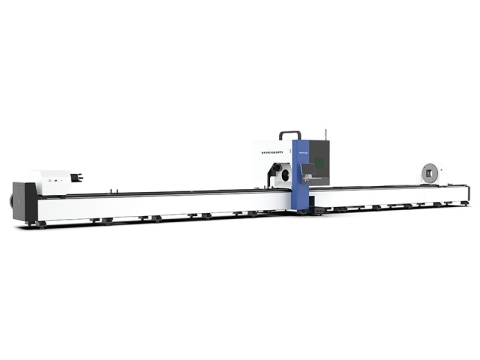

I-Industrial Tube Laser Cutter yamapayipi ensimbi namaphrofayili

3D I-Tube Laser Bevel Cutting Machine ene-Automatic Feeder

I-hybrid laser cutter iyisistimu yokusika ehlanganisiwe ethengekayo ene-fiber kanye CO2 laser generator konke emshinini owodwa. Ngama-fiber lasers, ingasika izinsimbi ezijiyile, nge CO2 lasers, iyakwazi ukusika ama-nonmetals aminyene nezinsimbi ezincane. Umshini wokusika we-laser oyingxubevange uphinde ubhekisele kukhithi yokusika ezenzakalelayo esebenzisa amandla aphezulu CO2 ithubhu le-laser elivalwe ngokuhlanganisa ugongolo lokusika izinsimbi ezincane njengensimbi, i-aluminium, ithusi, ithusi, i-titanium, insimbi, isiliva, igolide ne-alloy, kanye nokusika izinto ezingezona ezensimbi ezifana neplywood, izinkuni, i-MDF, i-acrylic, ipulasitiki, indwangu kanye nesikhumba. Ithebula le-hybrid laser cutting lilingana 2x3, 4x4, 4x8, 5x10, Futhi 6x12, engenziwa ngezifiso njengezidingo zebhizinisi lakho. Ithuluzi elingcono kakhulu lokusika ibhajethi lakho kokubili ukusetshenziswa kokuzilibazisa kanye nokukhiqizwa kwezimboni.

I-Metal & Nonmetal Laser Cutter nge 300W CO2 I-Laser Tube

I-Fiber & CO2 I-Combo Laser Cutting System ye-Metal & Nonmetal

4x8 I-Flatbed Laser CNC Eqopha Umshini Wokusika Uyathengiswa

2025 Umshini Ongcono Kakhulu Wokusika Insimbi Nonmetal Odayiswayo

IHybrid yokuzilibazisa CO2 I-Laser Cutter ye-Metal & Nonmetal

Umshini Wokusika Okuxubile we-CNC Laser Cutter Hybrid

Isici Izindaba On Laser Cutting

Khetha Umshini Wakho Woku-1 Wokusika I-Laser Wokusetshenziswa Kwasekhaya Nezimboni

Awudingi ukuba nenkampani enkulu ukuze ubambe i-laser cutter yakho elandelayo. Eminyakeni yamuva, kunezinketho eziningi ezithengekayo ezitholakalayo ezizokuvumela ukuthi uthathe isisombululo sakho esilandelayo sokusika ngaphandle kokuphula ibhange lakho. Kodwa ngesikhathi esifanayo, kubalulekile ukuthi uqaphele ngokuthenga njengoba ikhwalithi ibalulekile ekupheleni kosuku. Bheka umshini onembile, onokwethenjelwa onezingxenye zekhwalithi ephezulu, futhi uqiniseke ukuthi uthola ukuqeqeshwa okufanele nokusekelwa. Cabangela izidingo zakho ezithile kanye nesabelomali lapho ukhetha ikhithi yamathuluzi okusika okuzenzakalelayo, bese ukhetha leyo ehambisana kangcono nezidingo zakho. Ngesistimu yokusika ehlakaniphile, ungakwazi ukufeza imigomo yakho yokukhiqiza ngaphandle kokusebenzisa imali ngokweqile. Ngaphezu kwalokho, ngokusungulwa okuqhubekayo nokuthuthukiswa kwe-Industry 4.0 kanye nobuhlakani bokufakelwa, ubuchwepheshe bokusika i-laser buzohlanganiswa namarobhothi ezimboni ukuze kuzuzwe ukusika okuzenzakalelayo kanye nedijithali, ukuthuthukisa isivinini sokusika, ukujiya, ukunemba kanye nekhwalithi. Uma kwenzeka ufuna umakhi omethembayo kanye nomkhiqizo ukuze uthenge umshini wakho wokusika we-laser olandelayo ngentengo ethengekayo, STYLECNC kungaba indawo enhle kakhulu yokuthembela kuyo.

Incazelo Nencazelo

I-laser cutter iyithuluzi lokusika elizenzakalelayo elisebenzisa i-laser kanye nohlelo oluhlakaniphile lokusika lwedijithali ukusika amaphethini ezinsimbi (insimbi, ithusi, ithusi, i-aluminium, i-titanium, igolide, isiliva, i-alloy, insimbi), i-acrylic, irabha, ukhuni, i-plywood, i-MDF, ipulasitiki, isikhumba, iphepha, igwebu, izindwangu nendwangu. Ikhithi yokusika i-laser iqukethe isisekelo somshini kanye nohlaka, isilawuli se-CNC, ijeneretha, amandla kagesi, ishubhu, ikhanda, ilensi, isibuko, i-chiller yamanzi, i-stepper motor noma i-servo motor, isilinda segesi, i-compressor yomoya, ithangi lokugcina igesi, ifayili yokupholisa umoya, isikhipha uthuli, isomisi nesoftware.

Uhlelo lokusika i-laser luyiqoqo elihlelekile lezingxenye ezididiyelwe ukuze kufezwe ukusikeka okunembayo kokukhiqizwa kwezimboni, ukusetshenziswa kwezohwebo, imfundo, ukuqeqeshwa, amabhizinisi amancane, ibhizinisi lasekhaya, isitolo esincane, nesitolo sasekhaya. Kuyisistimu yokusika eguquguqukayo uma kuqhathaniswa namathuluzi okusika okwenziwa ngesandla kanye nemishini. Ingakwazi ukusika izinto ezihlukahlukene ngobukhulu obuhlukahlukene futhi akukho mkhawulo kumajamo ongawathola. Kuyashesha ukuhlela futhi noma yiziphi izinguquko zingasetshenziswa kunoma yisiphi isigaba sokukhiqiza cishe ngaphandle kwezindleko ezengeziwe nesikhathi. Isebenza ngokunemba okuphezulu, ikhwalithi enhle kakhulu yokunquma futhi akukho ukuguquguquka kwezingxenye. Kuyisixazululo esingcono kakhulu se-modularization kanye ne-automation emjikelezweni wokukhiqiza.

Indlela Esebenza

I-Laser beam wuhlobo lokukhanya olusuka ekuguqukeni kwama-athomu (ama-molecule noma ama-ion). Nokho, ihlukile ekukhanyeni okuvamile ngoba incike emisebeni ezenzakalelayo kuphela isikhathi esifushane kakhulu. Inqubo elandelayo inqunywa ngokuphelele imisebe evusa amadlingozi, ngakho inombala omsulwa kakhulu, cishe akukho ukuhlukana kwesiqondiso, kanye nokuqina okukhanyayo okuphezulu kakhulu, nokuhambisana okuphezulu.

Ukusika nge-laser kuyinqubo ezenzakalelayo esebenzisa amandla aphezulu kanye nokuminyana okuphezulu kusuka ensikeni yokukhanya egxilile ukuze inyibilike futhi ihwamulise insimbi, ukhuni, i-acrylic, ipulasitiki, indwangu, isikhumba, igwebu, nezinye izinto, okuholela ku-kerf enembile.

Ngesilawuli se-CNC, i-generator ikhipha i-high-frequency ukwenza i-beam ene-frequency ethile nobubanzi be-pulse. I-beam idluliselwa futhi iboniswa ngendlela ye-optical futhi igxilwe yiqembu le-lens eligxilile. Indawo yokukhanya encane, enamandla amakhulu-amandla aphezulu yenziwa phezu kwengxenye, indawo okugxilwe kuyo itholakala eduze kwendawo ezosikwa, futhi impahla iyancibilika noma ihwamuke lapho izinga lokushisa liphezulu ngokushesha. I-pulse ngayinye idubula imbobo encane ku-substrate. Ngesilawuli sezinombolo sekhompiyutha, ikhanda ne-substrate yenza ukunyakaza okuhlobene okuqhubekayo kanye namachashazi ngokuya ngefayela eliklanyelwe, ukuze kusike i-substrate ibe yisimo esifunwayo. Imingcele yezobuchwepheshe (isivinini sokusika, amandla, ingcindezi yegesi) kanye ne-trajectory yokunyakaza ngesikhathi sokuhlukaniswa kulawulwa uhlelo lwe-CNC, futhi i-slag emgqeni ishaywa yigesi elisizayo ngokucindezela okuthile. I-beam ekhishwa i-generator igxile ohlelweni lwe-optical path ibe ugongolo lokuminyana kwamandla aphezulu. I-beam ifakwe imisebe ebusweni bengxenye ukuze ilethe ingxenye endaweni yokuncibilika noma iphoyinti elibilayo, kuyilapho i-coaxial ye-high-pressure coaxial ene-beam iphephetha into encibilikisiwe noma ehwamuke. Njengoba ugongolo lunyakaza ngokuhlobene nengxenye, impahla iyasikwa ekugcineni, ngaleyo ndlela kufezwe inhloso yokusika. Amandla ahlukene angasika amaphrojekthi ahlukene ngobukhulu obuhlukene. Ngokuvamile, amandla aphezulu engxenyeni enkulu. Kufanele wenze ukukhetha okufanele ngokwezidingo zakho.

Izinhlelo zokusebenza nokusetshenziswa

Ama-Lasers angamathuluzi okusika ahlukahlukene asetshenziswa ezinhlotsheni eziningi zezinhlelo zokusebenza, okuhlanganisa ukwenza kube ngokwakho (ukwenza ngokwezifiso), ukuphrinta kwedijithali, ubuchwepheshe bezokwelapha, amalebhu endwangu, imfundo, amamodeli ezakhiwo, amafoni ahlakaniphile namakhompyutha aphathekayo, amakhompyutha & nogesi, amathoyizi, amawashi, ubuciko nemisebenzi yezandla, imiklomelo, izindondo, izitembu zenjoloba, ukwenza izimpawu, ukwenza amatshe, ukuklama, ukwenza amatshe imboni yezogesi, imboni yezimoto, izimpawu, ubunjiniyela bemishini, amabhola, ukwenza ubucwebe, izindwangu zemfashini nezembatho, ama-stencil, amakhadi wephepha, omati baphansi bezimoto namalayini, imboni yendwangu nezingubo, izinombolo zesiriyeli zekhodi yebha, amawashi, imboni yokwenza imishini, imboni yamapuleti edatha, imboni yokupakisha.

I-Laser Cuttable Materials

Abasiki be-laser bangasika kalula ezinhlobonhlobo zezinto ezisetshenziswayo, okuhlanganisa izinsimbi, ama-nonmetals nama-metalloids, kanye nezinye izinhlanganisela.

Ama-laser e-fiber ayakwazi ukusika izinhlobonhlobo zezinto zensimbi, okuhlanganisa i-carbon steel, insimbi engagqwali, insimbi emnene, insimbi yamathuluzi, insimbi yasentwasahlobo, insimbi ebilisiwe, i-aluminium, ithusi, igolide, isiliva, i-alloy, i-titanium, insimbi, ithusi, i-manganese, i-chromium, i-nickel, i-cobalt, umthofu, nezinye izinsimbi ukudala ubujamo, amashubhu ensimbi, amashubhu ensimbi, amashidi ensimbi. 3D izinsimbi ezigobile, nezinsimbi ezingajwayelekile.

CO2 ama-laser anekhono lokusika izinsimbi eziningi ezincanyana nezingezona izinsimbi, i-metalloids, nezinhlanganisela, okuhlanganisa ukhuni, i-MDF, iplywood, i-chipboard, i-acrylic, ipulasitiki, i-PMMA, isikhumba, indwangu, amakhadibhodi, iphepha, irabha, igwebu le-depron, isikhumba sokhuni, iphepha lezinkuni, i-EPM, igwebu le-gator, i-polyester (PES), i-polyethylene, i-bambolo, i-polyethylene, i-PU izinyo lendlovu, imicu ye-carbon, i-beryllium oxide, i-polyvinyl chloride (PVC), i-polyvinyl butyrale (PVB), i-polytetrafluoroethylenes (PTFE / Teflon), ama-phenolic noma ama-epoxy resins, nanoma yiziphi izinto ezinama-halogens (i-fluorine, i-astatine, iodine, i-chlorine, i-bromine).

Imininingwane

| Brand | STYLECNC |

| izinhlobo | I-Fiber Lasers, CO2 Lasers |

| I-Laser Wavelength | 10.6 μm, 1064 nm |

| Amandla | 80W, 100W, 130W, 150W, 180W, 300W, 1500W, 2000W, 3000W, 4000W, 6000W, 10000W, 12000W, 15000W, 20000W, 30000W, 40000W, 60000W |

| Osayizi Bethebula | 2' x 3', 2' x 4', 4' x 4', 4' x 8', 5' x 10', 6' x 12' |

| Axis | 3 i-eksisi, 4th axis (Rotary axis), 4 axis, 5 axis |

| Ukusika Izinto | Izinsimbi (Stainless Steel, Carbon Steel, Tool Steel, Galvanized Steel, Spring Steel, Copper, Brass, Aluminium, Gold, Silver, Iron, Titanium, Chromium, Alloy, Manganese, Cobalt, Nickel, lead), Wood, MDF, Plywood, Chipboard, Acrylic, I-Pastic, I-ather, I-Plastic I-PE, EPM, PES, PVB, PUR, PVC, PTFE, PMMA. |

| Isoftware yokusika | I-LaserCut, CypCut, RDWorks, LaserWeb, EZCAD, CypOne, Laser GRBL, EzGraver, SolveSpace, Inkscape, LightBurn, Corel Draw, Adobe Illustrator, Archicad, AutoCAD. |

| Izicelo | Ukukhiqiza Izimboni, Imfundo Yesikole, Amabhizinisi Amancane, Ibhizinisi Lasekhaya, Isitolo Esincane, Isitolo Sasekhaya, Abathanda Ukuzilibazisa. |

| Price Range | $2,600 - $1, I-000,000 |

Izindleko Nezintengo

Uma ubheka ukuqala ibhizinisi lakho ngethuluzi elisetshenzisiwe noma elisha lokusika i-laser ukwenza imali, ungase uzibuze ukuthi izobiza malini? futhi yiziphi izindleko ezijwayelekile emakethe? Ngokusho kokuhlaziywa kwedatha enkulu, abasiki be-laser abashibhile babiza nxazonke $2, 600, nezindleko ezibiza kakhulu ezifika ku $300,000, ngaphandle kwentengo yokuthutha, amanani entela, imvume yentela, isevisi, nokusekelwa kwezobuchwepheshe. Izindleko zangempela zincike ohlotsheni, uhlobo, imodeli namandla, kanye nokuthi ufuna noma yiziphi izici ezengeziwe, okuhlanganisa ukwakheka komuntu siqu, usayizi wetafula ngokwezifiso, ijeneretha namandla, okunamathiselwe okujikelezayo, isilawuli, isofthiwe, izingxenye, izesekeli, ukuthuthukiswa, ukusetha, ukulungisa iphutha, nezinye izici ezikhethekile. Nalu uhlu lwezindleko ezimaphakathi 2025.

Umshini wokusika i-fiber laser ngokuvamile ubiza noma yikuphi ukusuka $14,000 kuya ku-1,000,000. Izintengo ze CO2 ama-laser cutters ahluka phakathi $2, 600 kanye 20,000 ngokwesilinganiso. Uhlelo lokusika oluxubile lwe-laser oluxubile luqala ngo $6,800 futhi ukhuphukele phezulu $32,500. Ungathenga izinhlobonhlobo zezinketho nezengezo ezifanele ibhizinisi lakho, kusukela ezindaweni ezizungezile $10 wezingxenye ezisebenzisekayo kanye nezinsiza, nokukhuphukela ku $36,000 wamajeneretha e-laser we-fiber enamandla aphezulu.

Kusukela kuzinga lokungena ukuya ezinhlotsheni ezisezingeni eliphezulu noma ezilungele imvelo, izindleko ziyahlukahluka kuye ngezici namandla owakhethayo.

Amakhithi wokusika we-laser angabizi kakhulu ahluka ngentengo ukusuka $2,600 kube $5, 600, iqala nge 80W CO2 ishubhu yengilazi yabaqalayo, abathanda ukuzilibazisa kanye nabathandi, abasebenzisi basekhaya nabanikazi bamabhizinisi amancane, kanti eminye imishini yokusika i-laser ephezulu ibiza kakhulu $1000,000 nge 60000W Ama-laser fiber we-IPG anamandla aphezulu okusikeka kwensimbi okujiyile.

I-Budget-friendly laser cutting system inenani elivela $3,000 kube $10,800 nge CO2 laser ongakhetha amandla ka 80W, 100W, 130W, 150W, 180W nge-plywood, i-MDF, i-bamboo, indwangu, isikhumba, i-acrylic, indwangu, negwebu.

Izimboni ezithengeka kakhulu laser sheet metal umsiki of 2025 iqala $6,800 nge 300W CO2 laser tube, kuyilapho amanye amamodeli ukunemba isukela $1I-4,000 kuya $1000,000 ngezinketho zamandla we-fiber laser we 1500W, 2000W, 3000W, 4000W, 6000W, 10000W, 12000W, 15000W, 20000W, 30000W, 40000W, Futhi 60000W.

Umshini wokusika amashubhu we-laser ochwepheshe uza nenani lentengo okungenani $50,000 ngesilawuli se-CNC sanoma yiziphi izinhlobo zamashubhu ensimbi.

Kuzodingeka usebenzise $4I-2,500 kuya $116,000 ukuthenga i-laser sheet sheet metal yonke-in-one kanye ne-tube cutter nge-automation ukuze kusetshenziswe izinjongo ezimbili zokuthengisa.

Irobhothi eliyi-automatic 5 axis laser cutting lisukela $4I-9,000 kuya $83,500 ukuze kube nezimo 3D ukusikeka kwensimbi okuguquguqukayo kwama-angle amaningi kanye ne-multi-dimensional ekukhiqizeni izimboni.

QAPHELA: I 1000W inketho yamandla e-laser inqanyuliwe futhi ayisatholakali, ithathelwe indawo ukuthuthukiswa kwamahhala kokuthi 1500W.

Thatha Ibhajethi Yakho

| izinhlobo | Intengo encane | Inani Eliphezulu | Inani eliphansi |

|---|---|---|---|

| Isigaba sokuqala | $2,600 | $5,200 | $3,980 |

| Okuthandwayo | $3,280 | $7,500 | $5,210 |

| Umdlandla | $3,960 | $8,800 | $6,380 |

| professional | $5,900 | $16,800 | $9,120 |

| Commercial | $7,800 | $23,200 | $12,300 |

| Industrial | $9,600 | $61,500 | $15,600 |

| Enterprise | $12,700 | $300,000 | $18,900 |

| CO2 | $2,800 | $20,000 | $6,720 |

| Fiber | $14,000 | $1000,000 | $32,600 |

| Wood | $3,200 | $18,000 | $5,180 |

| acrylic | $3,800 | $8,000 | $5,600 |

| Indwangu | $6,500 | $12,000 | $8,100 |

| Foam | $5,200 | $10,800 | $6,900 |

| Metal | $6,500 | $1,000,000 | $10,250 |

Izinhlobo Nezigaba

Imishini yokusika i-laser ihlanganisa i-fiber lasers kanye CO2 ama-laser asekelwe emithonjeni ye-laser ehlukene. Ama-Laser cutters afika ngezinhlobo eziphathwayo, eziphathwayo, ezincane, ezincane, zedeskithophu kanye ne-gantry ngokuya ngezitayela nokubukeka okuhlukile. Amatafula okusika i-laser ayatholakala ku 2x3, 2x4, 4x4, 4x8, 5x10 futhi 6x12 kuye ngosayizi webhentshi (indawo yokusebenza). Ngaphambi kokuthenga, sicela ulinganise indawo yakho yokusebenzela ukuze uqinisekise ukuthi ilingana ncamashi futhi uthole ikhithi yetafula elungile. Amasistimu wokusika ama-laser ahlukaniswe abe yi-3-eksisi, 4th-eksisi (i-axis ejikelezayo), i-4-eksisi, i-5-eksisi kanye ne-multi-eksisi. 3D amarobhothi ukuze abhekane nokusika ngezindlela ezahlukene nama-engeli. Ungahlangana namatafula okusika ama-flatbed, ama-tube cutters, amathuluzi okusika asekhaya, amakhithi okusika okuzilibazisa, ama-die cutters, amasistimu wokusika iphrofayili, nemishini yokusika yezimboni ezinhlobonhlobo zezicelo ezisebenzayo. Ngokuphathelene nezinto zokusika, ungazibiza ngabasiki be-laser bensimbi, izinkuni, indwangu, isikhumba, iphepha, i-acrylic, ipulasitiki, igwebu, iphepha, nokuningi.

Imihlahlandlela ye-DIY

Njenge-DIYer, uma unombono wokwakha nokwenza ikhithi ye-laser, kufanele uqale uqonde ukwakheka kwayo kwesakhiwo. Ikhithi ephelele iqukethe izingxenye ezibalulekile ezifana nejeneretha, ikhanda lokusika, izingxenye zokuhambisa uthango, itafula lokusebenza, isilawuli se-CNC, nesistimu yokupholisa.

I-Laser Generator

Kuyingxenye eyenza i-beam. I-Fibre iwuchwepheshe bazo zonke izinhlobo zeshidi lezinsimbi namashubhu ensimbi. CO2 iyonga ngokhuni, ipulasitiki, i-acrylic, indwangu, isikhumba, igwebu, nezinsimbi ezincane.

Ukunquma iNhloko

Yakhiwe ngombhobho, ilensi yokugxila kanye nohlelo lokulandela umkhondo.

Ukusika Nozzle

Kunezinhlobo ezi-3 ezijwayelekile zamadumba emakethe, okuhlanganisa ukuhambisana, ukuguquguquka, kanye ne-conical.

Ilensi yokugxila

Gxila kumandla we-beam futhi wakhe indawo ephezulu yokuminyana kwamandla. Ilensi yokugxilisa ingqondo emaphakathi nendawo ende ifaneleka kupuleti oluwugqinsi, futhi inezidingo eziphansi ekuzinzeni kwezikhala zesistimu yokulandelela. Ilensi yokugxila emfushane ifaneleka kuphela eshidini elincanyana, elidinga ukuzinza kwesikhala esiphezulu sohlelo lokulandela umkhondo futhi linciphisa kakhulu izidingo zamandla okukhiphayo.

I-Focus Tracking System

Isistimu yokulandelela okugxilwe kuyo yenziwe ngekhanda lokusika le-auto focus kanye nesistimu yezinzwa zokulandelela. Ikhanda lokusika lakhiwe izingxenye zokulungiswa kwemishini, isistimu yokuvunguza komoya, isistimu yokuqondisa ukukhanya, nesistimu yokupholisa amanzi. Inzwa iqukethe ingxenye yokulawula ukukhulisa i-amplification kanye ne-elementi yenzwa. Kunezinhlobo ezingu-2 zezinhlelo zokulandela umkhondo, enye isistimu yokulandelela inzwa ye-inductive (eyaziwa nangokuthi isistimu yokulandelela othintana naye), enye isistimu yokulandelela inzwa ye-capacitive (eyaziwa nangokuthi isistimu yokulandelela okungaxhunywanga).

Izingxenye Zokulethwa Kwe-Beam

Ingxenye eyinhloko yomhlangano wokulethwa kwe-beam yisibuko se-refractive, esisetshenziselwa ukuqondisa ugongolo ngendlela oyifunayo. I-reflector ngokuvamile ivikelwe isembozo sokuzivikela, futhi igesi evikelekile yokucindezela ehlanzekile yethulwa ukuvikela ilensi ekungcoleni.

Ithebula Lokusika

Ithebula lakhiwe ngohlaka lombhede kanye nengxenye yokushayela, esetshenziselwa ukubona ingxenye engumshini yokunyakaza kwe-eksisi X, Y, Z.

Isilawuli se-CNC

Isilawuli se-CNC sisetshenziselwa ukulawula ukunyakaza kwezimbazo ze-X, Y kanye no-Z, futhi setha imingcele yokusika njengamandla nesivinini.

Ukuphola System

Isistimu yokupholisa ibhekisela kumshini wokupholisa amanzi, osetshenziselwa ukupholisa umshini. Isibonelo, izinga lokuguqulwa kwe-electro-optical lingama-33%, futhi cishe u-67% wamandla kagesi aguqulwa abe amandla okushisa. Ukuze kuqinisekiswe ukusebenza okuvamile kwemishini, i-chiller idinga ukupholiswa ngamanzi ukuze kuncishiswe izinga lokushisa lomshini wonke.

Hlanganani

Ngemva kokucwaninga nokuthenga izingxenye nezinye izinsimbi, umsebenzi osele uwukuhlanganisa ikhithi nokulungisa iphutha lesofthiwe nehardware. Ukusebenza kanye nekhwalithi yokusika yomshini kuhlobene ngokuqondile nezinto ezibonakalayo, i-generator, igesi, ukucindezela komoya kanye nemingcele oyibekayo. Sicela usethe amapharamitha ngokucophelela ngokwezidingo zenqubo yakho. Ukusethwa kwepharamitha okungalungile kanye nokusebenza kungase kubangele umphumela oncishisiwe, ukulimala kwekhanda lokusika noma ezinye izingxenye zomshini, noma ngisho nokulimala komuntu siqu.

Imiyalo yokusebenza

Ukusika i-laser ubuchwepheshe bokukhiqiza obungathinteki obusetshenziswa ukusika izinto emabhizinisini amancane nasezimbonini zokukhiqiza. I-laser ikhipha i-beam egxile kumandla aphezulu encibilikisa okokusebenza futhi ishiye unqenqema ngokuqedwa kwendawo ephezulu yekhwalithi ephezulu. Ngezinzuzo zayo ezivelele zobuchwepheshe, ukusetshenziswa kwamandla aphansi kakhulu, ukunganakeki, izindleko zokusebenza ezincishisiwe kanye nokusebenza okuphindaphindwayo nokunembayo kokumisa, uhlelo lokusika ugongolo lwe-laser lusungule ibhentshimakhi entsha yokusika okuyinkimbinkimbi kanye nezinga elisha lokuhlolwa kwekhwalithi yenqubo.

Ngaphambi kokuqala, kufanele wenze amalungiselelo alandelayo:

Okokuqala, kufanele sihlole ukuthi konke ukuxhumana emshinini (okuhlanganisa amandla, i-PC, nesistimu yokukhipha umoya) kulungile futhi kuxhunywe ngendlela efanele. Bheka ngokubuka isimo somshini. Qiniseka ukuthi zonke izindlela zihamba ngokukhululeka futhi uhlole ukuthi akukho yini okubalulekile ngaphansi kwetafula lokucubungula. Qinisekisa ukuthi indawo yokusebenza kanye nezingxenye ze-optical zihlanzekile futhi uzihlanze uma kunesidingo. Ukuze uthole ulwazi olwengeziwe ngalolu daba, sicela ufunde ingxenye ethi "Isondlo Esijwayelekile" semanuwali yokusebenza. Hlola isistimu ye-exhaust bese uqala uhlelo lokupholisa uma kunesidingo. Hlola ukuthi izihlungi kanye nekhabhoni ecushiwe yesistimu yokukhipha umoya kufakwe ngokwemiyalo, bese uvala ikesi lokuvikela ngemuva kokuhlola.

Okulandelayo, cindezela inkinobho enkulu ukuze uvule umshini. Uma wonke amakhava anama-circuit breaker evaliwe, isistimu izoqala ukukhala ngemva kokuqaliswa. Ngemva kokuvula umshini, itafula lizohamba liye phansi, kuyilapho ikhanda lokusika lithuthela endaweni ye-zero (etholakala ekhoneni eliphezulu kwesokunxele). Uma kunomsindo nesibani se-LED sikhanya kancane futhi kancane, inqubo ye-chime iqedwe ngendlela efanele futhi umshini usulungele ukuqala ukusebenza.

Ngemuva kokuthi wonke amalungiselelo eseqediwe, sicela ulandele izinyathelo eziyi-15 zokusebenza okulula ukuzilandela:

Isinyathelo 1. Lungisa izinto ngokuqhubekayo etafuleni lokusika.

Isinyathelo sesi-2. Lungisa imingcele yokusika yesilawuli se-laser ngokusho kohlobo nokushuba kwezinto.

Isinyathelo sesi-3. Hlanganisa umlomo wombhobho kanye nelensi efanayo, bese ubheka ukuthi ukubukeka nokuhlanzeka kwazo kulungile yini.

Isinyathelo sesi-4. Susa iphutha bese uhambisa ukugxila kwekhanda elisikayo endaweni efanele.

Isinyathelo sesi-5. Beka phakathi umlomo wombhobho.

Isinyathelo 6. Linganisa inzwa.

Isinyathelo sesi-7. Khetha igesi esebenzayo efanele ngokwezidingo zakho zomsebenzi.

Isinyathelo sesi-8. Hlola ukusika izinto bese ubheka ukuthi unqenqema lokusika lubushelelezi futhi ukusika kunembile. Uma kukhona ukuchezuka, lungisa imingcele yokusika ngokufanele ize ihlangabezane nezidingo zakho.

Isinyathelo 9. Dweba futhi uhlele amafayela wesithombe, futhi uwangenise ohlelweni lokulawula ukusika.

Isinyathelo 10. Ngemuva kokuthi wonke amalungiselelo eselungile, ungaqala ukusebenza.

Isinyathelo 11. Ngesikhathi sokusebenza, abasebenzi kudingeka babheke ukusebenza kwemishini esizeni. Uma kunesimo esiphuthumayo, cindezela inkinobho yokumisa ngokushesha ngangokunokwenzeka.

Isinyathelo 12. Uma umshini uyeka ukusebenza, kufanele uhlanze ama-rails omhlahlandlela njalo, usule ifreyimu yemishini, futhi usebenzise amafutha okugcoba emigwaqweni yokuqondisa njalo ukuze uqinisekise ukuthi ayikho imfucumfucu.

Isinyathelo 13. Hlanza indandatho yemoto njalo ukuze uqinisekise ukusebenza okuvamile komshini nokusika okunembile ukuze uqinisekise ikhwalithi.

Isinyathelo 14. Abasebenzi kufanele basebenzise isicoci se-vacuum ukususa uthuli nemfucumfucu emshinini masonto onke ukuze baqinisekise ukuhlanzeka kwempahla.

Isinyathelo 15. Abasebenzi kudingeka bahlole ubuqotho nokuma kwethrekhi njalo ezinyangeni eziyisi-6 ukuze baqinisekise impilo yesevisi yomshini. Uma kukhona okungavamile kutholakala, kufanele kugcinwe futhi kulungiswe ngesikhathi.

Khetha Okwakho

Uma unomqondo wokuthenga umshini wokusika we-laser, kunezinto eziningi okufanele uzicabangele. Ake sikwenzele icebo lokuthenga elinemininingwane.

Ukuhlela i-Laser-cut Yakho

Okokuqala, udinga ukubheka ezinye izici ezifana nesikali sebhizinisi lakho, yiziphi izinto okudingeka uzisike, ukuthi izinto ziwugqinsi kangakanani, bese uqinisekisa ukunikezwa kwamandla kanye nosayizi webhentshi lomsebenzi ngokwezidingo zakho. Njengamanje, amandla e-laser emakethe asukela 80W kuya 40,000W, futhi usayizi wetafula ungenziwa ngokwezifiso ngokwezidingo zakho.

Icwaninga Abakhiqizi Nabenzi

Uma uqinisekisa izidingo zakho, ungahamba uyokwenza ucwaningo ngakho. Mhlawumbe ungafunda kontanga yakho, futhi uqonde imisebenzi yomshini namapharamitha ayisisekelo. Khetha abakhiqizi abambalwa abanamandla abanamanani avumayo ukuze wenze ukushintshana kokuqala nokuqinisekisa, bese wenza uphenyo esizeni esikhathini esizayo, bese uqhuba izingxoxo ezinemininingwane eminingi ngezintengo, ukuqeqeshwa ku-inthanethi nokungaxhunyiwe ku-inthanethi, kanye nezinsizakalo zangemuva kokuthengisa.

Ukukhetha Ijeneretha

Uma udinga ukusika ishidi lensimbi namashubhu ensimbi, i-fiber laser generator iyisinqumo esingcono kakhulu, esihlanganisa izinhlobo ezidumile ezifana ne-IPG, JPT, Raycus, kanye MAX. Uma ufuna ukuqopha nokusika izinkuni, i-acrylic, isikhumba, indwangu, i-A CO2 ingilazi laser tube ikhambi elilungile, okuhlanganisa ezinye brand ezidumile emhlabeni ezifana RECI kanye YONGLI.

Izidingo zamandla

Lapho ucwaninga ikhono lokusika, udinga ukucabangela ama-watts okunikezwa kwamandla. Uma usika amashidi amancane, ungakhetha ukunikezwa kwamandla okuphansi ukuze uhlangabezane nokusika kwakho. Izinto ezinogqinsi oluphakeme zidinga ukucabangela ukunikezwa kwamandla aphezulu, okuzuzisa amabhizinisi ukulawula izindleko.

Ukukhetha Izingxenye Nezesekeli

Kufanele unake ngokukhethekile izingxenye ezinkulu ekuthengeni, njengejeneretha ye-laser, isilawuli, ikhanda elisikayo, imoto, i-water chiller, i-air compressor, isilinda segesi, ithangi lokugcina igesi, isomisi esibandayo, isihlungi, isikhipha uthuli, isikhiphi se-slag. Izinga lalezi zingxenye lihlobene nesivinini sokusika nokunemba.

Ukukhetha Isofthiwe & Isilawuli

Ukuze wenze umshini ube lula ukuwusebenzisa, isilawuli esisebenziseka kalula nesoftware enamandla ye-CAD/CAM esuselwe ku-Windows ne-macOS ibalulekile. Ezinye zazo zimahhala ngemisebenzi elula, kuyilapho isofthiwe ekhokhelwayo ingochwepheshe kakhulu ebhizinisini lakho. Konke kuncike ezidingweni zakho zebhizinisi.

Ukuqinisekiswa Kwekhwalithi Nokuqina

Imikhiqizo yanamuhla ibuyekezwa ngokushesha futhi ngokushesha. Ngenxa yomjikelezo omfushane wokuthuthukiswa komkhiqizo, kukhona ukuhlukahluka komkhiqizo okwengeziwe, ukukhiqizwa kwesilingo sesampula, nokukhiqizwa ngobuningi. Ungawagcwalisa kanjani ama-oda ekhasimende ngekhwalithi nenani, ukuthuthukisa ukuncintisana kwezinkampani, nokugcina isithunzi senkampani nakho kuba njalo ngaso sonke isikhathi. Ngakho-ke, ukuthengwa kwemishini yokucubungula enemisebenzi ezinzile yisimo nesisekelo. Zama ukukhetha uhlobo olunesabelo esikhulu semakethe, isistimu yesevisi ezwakalayo ngemva kokuthengisa, inombolo enkulu yezitolo zesevisi yangemuva kokuthengisa, kanye nokuhlolwa kwenxanxathela yezitolo yesikhathi eside. Ukuhaha ukuthenga imikhiqizo yekhwalithi ephansi enamanani aphansi futhi engenayo isevisi yangemuva kokuthengisa, lokhu kuzoba nomthelela omubi kakhulu ekucutshungulweni kwamabhizinisi.

Isevisi Yangemuva Kokuthengisa Nokusekelwa

Isevisi yomkhiqizi ngamunye emva kokuthengisa ihlukile, futhi isikhathi sewaranti nayo ihlangene. Ngezingxenyekazi zekhompuyutha kanye nesofthiwe, kufanele kube nohlelo lokuqeqeshwa lochwepheshe ukusiza amakhasimende aqalise ngokushesha okukhulu. Kungakhathaliseki ukuthi umshini wenziwe kahle kangakanani, uzohlangabezana nezinkinga ezihlukahlukene lapho usetshenziswa. Uma amakhasimende ehlangabezana nezinkinga ezingaxazululeki, kubaluleke kakhulu ukuthi umenzi anganikeza izixazululo ngesikhathi esifanele. Lokhu futhi kuyinto ebalulekile okufanele icatshangelwe lapho uthenga.

Ukuthenga Inqubo Yokugeleza

Inqubo yokuthenga ngokuvamile iqala ngokunquma izidingo zakho nokubeka isabelomali, bese ucwaninga ngemishini yokusika i-laser, ukukhetha umphakeli, ukudala i-oda lokuthenga nokusayina inkontileka, ukucubungula ama-invoyisi, ukwenza izinkokhelo, ukwakha, ukuthumela, ukwamukela nokuhlola umshini wakho, futhi ekugcineni uphothula isivumelwano.

Investment & Izinzuzo

A CO2 umshini wokusika i-laser ulungele amakhasimende anesabelomali esiqinile, esinentengo kusuka $3,000 kube $16,000, nezici ezinezindleko eziphansi zokutshala imali, ukusetshenziswa okuncane kwezingxenye zokugqoka kanye nesikhathi sokukhokha esifushane. Kodwa-ke, ngenkathi ucubungula intengo, kufanele futhi ukhathalele ngenani elilethayo. Ngamanye amazwi, amandla ayo kanye nenzuzo inquma ukuthi kufanelekile yini ukutshala imali kuyo.

A CO2 Umshini we-laser kulula ukuwusebenzisa nge-CNC automation, esetshenziselwa ubuciko obunenzuzo ye-DIY, izipho nemisebenzi yobuciko. Uzakwethu omuhle kakhulu ongakusiza ukuthi uqale ibhizinisi lokwenza ngokwezifiso e-Amazon, noma udayise ama-laser omuntu siqu e-Etsy ukuze wenze imali, kufanelekile ukuthenga noma kunjalo.

Kodwa-ke, ingabe kufanelekile ukutshala imali emshinini wokusika we-fiber laser obizayo? Inenzuzo engakanani? Iningi lezinkampani noma abantu bangase bakhathazeke ngokuthi liyifanele yini intengo yalo uma uthenga. Umshini we-fiber laser oshibhe kakhulu uqala ngo $15,000, kanti umsiki obiza kakhulu ubiza kakhulu $1,000,000. Kuzothatha isikhathi esingakanani ukubuyisela izindleko zayo zokutshala, futhi ingangilethela inzuzo engakanani ngonyaka?

Uma ivolumu yebhizinisi lakho yanele, ungakwazi ukubuyisela ngokushesha izindleko zokutshala izimali, kuyilapho izinkampani eziningi zizithengela ukucubungula kwazo kwangaphakathi, ngevolumu encane uma kuqhathaniswa, futhi ukubuyisela izindleko kuzohamba kancane.

Ake sithathe ukucubungula kwangaphandle njengesibonelo. Njengamanje, inzuzo evamile yomshini we-laser wangaphandle iphakathi 50% futhi 60%. Uma isilinganiso sezindleko zokukhipha umsebenzi $5,000 ngenyanga, izindleko zonyaka $60,000. Uma ungumnikazi we-fiber laser, ngaphandle kwezindleko zenyanga engu-1 kanye nevolumu efanayo yokucubungula, izindleko zimayelana $2,500. Ngokwalesi sibalo, $3I-0,000 ingagcinwa ngonyaka, ngakho-ke amandla aphezulu 6000W i-fiber laser ingazikhokhela yona.

Impilo yesevisi yamajeneretha e-fiber laser ifika emahoreni ayi-100000 kodwa inqunyelwe. Akunakwenzeka ukuqhubeka nokuyisebenzisa ngaphandle kwezindleko. Ungakwazi ukubala izindleko zokusebenzisa ngemva kokusetshenziswa nangaphambi kokusetshenziswa. Bala ushintsho lwenzuzo ngemva kokusebenzisa umshini, ngemva kokukhipha izindleko zokutshala imali.

Izinzuzo & Cons

Ukusika i-Laser kuyindlela yokusika eshisayo, ekwazi ukwenza ukuhwamuka, ukuhlanganisa nokusika umoya-mpilo, ukudayela nokuphuka okulawulwayo. Ithathe indawo yabasiki bemishini bendabuko ngemishayo engabonakali. Inezinzuzo zejubane eliphezulu, ukunemba okuphezulu, ikhwalithi ephezulu, izindleko zomshini eziphansi, ukusetha ngomshini okuzenzakalelayo, imiphetho yokusika ebushelelezi yanoma yikuphi ukuma nemiklamo. Iwukuthuthukiswa kwamathuluzi okusika endabuko. Ngaphezu kwezinzuzo, ibuye ibe nokushiyeka kwayo kanye nokulinganiselwa kwayo.

buhle

• Ingxenye yemishini yekhanda lokusika ayinakho ukuthintana nengxenye, futhi ngeke iklwebhe ubuso bengxenye ngesikhathi sokusebenza.

• Ijubane lokusika liyashesha, ukusika kubushelelezi futhi kuyisicaba, ngokuvamile akukho ukusika okulandelayo okudingekayo.

• Indawo ethintekile ekushiseni incane, i-deformation yeshidi incane, esetshenziselwa ukusika okuhle ngokunemba.

• Izindleko eziphansi zokusetshenziswa ngaphandle kwezinto ezisetshenziswayo, okuyinzuzo kubenzi ukunciphisa izindleko zokukhiqiza.

• I-slit ayinakho ukucindezeleka komshini, ayikho i-shear burr. Ukunemba okuphezulu, ukuphindaphinda okuhle, akulimazi ingaphezulu lezinto ezinomkhawulo wokusika obushelelezi.

• Kusetshenziswa iyunithi yokulawula izinombolo zekhompuyutha (CNC) eyamukela ukusika idatha kusuka endaweni yokusebenza ye-computer-aid design (CAD).

• Ukusebenza nohlelo lwe-CNC, olungasika noma yiluphi uhlelo, kanye nengxenye yonke yefomethi enkulu ngaphandle kokubunjwa.

bawo

• Njengoba kuwukusika okushisayo, inqubo yokusika izingqimba eziningi, ingxenye enqenqemeni ilula ukunamathela, enomthelela omkhulu kwikhwalithi.

• Ngenxa yobude obufushane be-laser, kulula ukubangela umonakalo emehlweni abantu. Abasebenzisi bangakhetha ukugqoka izibuko ezikhethekile zokuzivikela ukuze banciphise ukulimala.

• Ngenxa yokusika okuncane kwe-fiber laser, ukusetshenziswa kwegesi kukhulu (ikakhulukazi uma kusebenza ne-nitrogen).

• Kusukela CO2 I-laser tube yenziwe ngengilazi, ukuphatha okungalungile kuyobangela ukuba iphuke.

Ukunakekelwa Nokunakekelwa

Umshini wokusika we-laser kufanele ugcinwe njalo ukuze kuqinisekiswe ijubane lokusika, ukunemba, kanye nekhwalithi, futhi wandise impilo yawo yenkonzo. Kufanele wakhe imikhuba emihle yokusebenza engu-7 ebalwe ngezansi.

• Ngaphambi kokuqala umshini nsuku zonke, hlola ngokucophelela ingcindezi yegesi esebenzayo kanye negesi yokusika. Uma ingcindezi yegesi inganele, kufanele ishintshwe ngesikhathi.

• Hlola ukuthi amaphoyinti anguziro we-eksisi engu-X, i-eksisi ye-Y, ne-axis engu-Z, isimo esilungele i-laser nezinye izinkinobho zonakele yini, nokuthi ingabe amaswishi anomkhawulo we-eksisi ngayinye azwela yini, nokuthi izikulufu zokukhweza ibhulokhi lokuhamba zikhululekile yini.

• Hlola ukuthi izinga lamanzi ajikelezayo ku-chiller lanele yini bese uligcwalisa.

• Hlola ukuthi ingabe kukhona ukuvuza emanzini ajikelezayo endlela yokubona yangaphandle. Ukuvuza kufanele kubhekwane nakho ngesikhathi, kungenjalo kuzofinyeza impilo ye-lens optical.

• Ngemva kokusebenza nsuku zonke, hlola ukuthi i-lens egxilile ayinamonakalo yini, futhi uhlole ukuthi indlela yokubona engaphandle ye-telescopic bellows ishile noma yonakele.

• Imfucumfucu kufanele igezwe ngesikhathi, indawo yokusebenza ihlanzwe, nendawo yokusebenza igcinwe ihlanzekile futhi icocekile. Ngesikhathi esifanayo, yenza umsebenzi omuhle wokuhlanza izinto zokusebenza ukuze uqinisekise ukuthi zonke izingxenye zemishini zihlanzekile futhi azinawo amabala, futhi akukho mfucumfucu engafakwa engxenyeni ngayinye yemishini.

• Ngemuva kokuthi umsebenzi wansuku zonke usuqediwe, vula i-valve yokukhipha ithangi lokugcina umoya phansi kwe-compressor yomoya ukuze ukhiphe amanzi, futhi uvale i-valve yokukhipha amanzi ngemuva kokukhishwa kwamanzi angcolile, bese uvala umshini bese uvala amandla amakhulu.

Izexwayiso Nezexwayiso

Osaqalayo noma uchwepheshe kufanele asebenzise umshini wokusika i-laser ngaphansi kokuqondisa kweziqondiso namathiphu okuphepha kubhukwana lomsebenzisi ukuze agweme izingozi. Kufanele ulandele imithetho yokuphepha eyi-18 esohlwini.

• Kufanele uhlanze ukungcola ohlakeni lombhede kanye nezinsimbi zokuqondisa nsuku zonke.

• Umsebenzisi kufanele alandele ngokuqinile imithetho yokusebenza kokuphepha.

• Umsebenzisi kufanele abheke wonke amamanuwali anikezwe umshini, ajwayele ukwakheka nokusebenza kwemishini, futhi abe nolwazi olufanele lwesistimu yokusebenza.

• Gqoka izinto zokuvikela abasebenzi njengoba kudingekile, futhi gqoka izibuko ezivikelayo ezihlangabezana nemithetho eduze komugqa.

• Ungacubunguli okokusebenza kuze kube yilapho sekunqunywa ukuthi ingabe into ingafakwa imisebe noma ishisiswe ukuze kugwenywe ingozi engaba khona yentuthu nentuthu.

• Lapho umshini uqalwa, u-opharetha ngeke akushiye okuthunyelwe noma aphathwe umphathiswa ngaphandle kokugunyazwa.

• Gcina isicishamlilo sitholakala kalula. Vala i-laser noma i-shutter uma ingasebenzi. Ungabeki iphepha, indwangu noma ezinye izinto ezivuthayo eduze kwenduku engavikelekile.

• Uma kutholakala okungavamile ngesikhathi sokucubungula, umshini kufanele umiswe ngokushesha, futhi iphutha kufanele liqedwe noma libikwe kumphathi ngesikhathi.

• Gcina ijeneretha, umbhede nezindawo ezizungezile zihlanzekile, zihlelekile futhi zingenawo uwoyela. Izinto zokusebenza, amapuleti nezilahliwe zipakishwa ngokwemithethonqubo.

• Uma usebenzisa amasilinda egesi, gwema ukumpintsha izintambo, amapayipi amanzi namapayipi omoya ukuze ugweme ukuvuza kukagesi, amanzi nomoya. Ukusetshenziswa kanye nokuthuthwa kwamasilinda egesi kufanele kuhambisane nemithetho ye-cylinder yegesi. Ungawavezi amasilinda egesi elangeni eliqondile noma eduze nemithombo yokushisa. Lapho uvula i-valve yebhodlela, opharetha kufanele ame eceleni komlomo webhodlela.

• Ngaphambi kokuvula amandla e-chiller, hlola izinga lamanzi le-chiller. Akuvunyelwe ngokuphelele ukuvula i-chiller lapho amanzi engekho noma izinga lamanzi liphansi kakhulu ukugwema ukulimala kwempahla yokupholisa amanzi. Kwenqatshelwe ngokuphelele ukukhama noma ukunyathela ipayipi lamanzi lokungena kanye nokuphuma kwe-chiller ukuze kugcinwe amaphaseji amanzi angavimbekile.

• Ugongolo luzobangela ukusha lapho lukhanyisa isikhumba somuntu. Ukugqolozela ugongolo isikhathi eside kungabangela umonakalo omkhulu ku-retina yeso. Abasebenzi kufanele bagqoke izibuko.

• Izinto ezisetshenziswayo zizokhipha intuthu eningi nothuli lapho zisika amapuleti athile, ngakho-ke ipayipi eliphumayo lefeni kufanele liyiswe ngaphandle, noma kufakwe idivayisi yokuhlanza umoya. Ngaphezu kwalokho, opharetha kufanele bagqoke imaski yothuli ukuvimbela ukuvela kwezifo emsebenzini.

• Uma izinga lokushisa lingaphansi kuka-0 °C isikhathi eside, amanzi okupholisa emshinini wokupholisa amanzi, i-laser kanye nepayipi lamanzi kufanele akhishwe ukuze kuvinjwe amanzi okupholisa ukuthi angabandi lapho izinga lokushisa liphansi kakhulu, okubangela ukulimala kwemishini namapayipi.

• Hlola ilensi yokuvikela ngaphakathi kwekhanda lokusika kanye ngosuku. Lapho isibuko se-collimating noma isibuko sokugxila sidinga ukuhlakazwa, bhala inqubo ye-disassembly. Naka ngokukhethekile indlela yokufaka i-lens futhi ungayifaki engalungile.

• Vala umthombo womoya namandla lapho uvaliwe, futhi ibhande lomoya eliyinsalela epayipini lomshini kufanele lithululwe ngesikhathi esifanayo. Uma ushiya umshini isikhathi eside, sicela uvale amandla ukuze uvimbele ukusebenza okungenamsebenzi.

• Naka ukubheka ukuthi akhona yini uwoyela wokugcoba ebusweni bomzila wesitimela ovundlile nobude kanye nohlaka lomshini, futhi ugcine ukuthambisa okuhle.

• Uma kukhona idivayisi yokulungisa i-h8 ezenzakalelayo, hlola ukuthi iyazwela yini nokuthi ithathelwe indawo uphenyo.

Umhlahlandlela Womthengi

Lapho uthenga i-laser cutter, kubalulekile ukugxila ezicini zobuchwepheshe ukuze uqinisekise ukuthi umshini uhlangabezana nezidingo zakho. Izici zobuchwepheshe ezibalulekile okufanele zicatshangelwe zihlanganisa amandla, indawo yokusika, ukulungiswa, nokuhambisana kwesofthiwe. Amandla e-laser anquma uhlobo nobukhulu bezinto umsiki angaphatha, kuyilapho indawo yokusika ibhekisela kusayizi wendawo yokusebenza. Ukulungiswa kunquma izinga lemininingwane kanye nokunemba umsiki angakuzuza. Kubalulekile futhi ukuqinisekisa ukuthi umsiki uyahambisana nesofthiwe ohlela ukuyisebenzisa. Inani kungenye into ebalulekile okufanele icatshangelwe lapho uthenga umshini wokusika we-laser. Izindleko zingahluka kuye ngokucaciswa kwayo kobuchwepheshe kanye nomkhiqizo. Kubalulekile ukulinganisa izindleko namandla omshini nokuthembeka ukuze uqinisekise ukuthi uthola inani elihle ngemali yakho. Ngokucabangela lezi zici zobuchwepheshe, ungenza isinqumo esinolwazi lapho ukhetha i-laser cutter kit & uhlelo lokusika oluzohlangabezana nezidingo zakho ezithile kanye nezidingo zakho.

Kungani STYLECNC?

STYLECNC ungumkhiqizi ohamba phambili wemishini yokusika i-laser ephezulu. Ngineminyaka engu-20+ yesipiliyoni embonini, STYLECNC izinikele ekuletheni ubuchwepheshe obusezingeni eliphezulu kanye nezixazululo ezintsha kumakhasimende ayo.

Kungakhathaliseki ukuthi udinga ukusika insimbi, ukhuni, noma ezinye izinto, uhlobo lunomshini okwazi ukuphatha umsebenzi. Ngaphezu kwemishini yayo esezingeni eliphezulu, ibhizinisi linikeza ukwesekwa kwamakhasimende okukhethekile kanye nesevisi. Ithimba lenkampani lochwepheshe liyatholakala ukuze liphendule noma yimiphi imibuzo futhi likunikeze usizo lokuqinisekisa ukuthi umshini wakho usebenza ngendlela engcono kakhulu.

Athini Amakhasimende Ethu?

Yini engakusondeza kithi kunezilinganiso eziwumgomo namazwana avela kumakhasimende angempela? Ngempendulo yamakhasimende ngobuhle nobubi be STYLECNCImishini yokusika i-laser, amaphuzu avelele kanye nokushiyeka kucacile ngokubuka nje. Izibuyekezo ezinhle zisikhuthaza ukuthi siqhubeke sisungula izinto ezintsha futhi siqhubekela phambili, kuyilapho ukubuyekezwa okungekuhle kusishukumisela ukuba siyeke amaphutha, silungise okunikezwayo kwethu futhi sihlangabezane kangcono nezidingo zakho. Esikufunayo ukwakha ukwethembana nawe futhi sizuze ubudlelwano besikhathi eside kunamazwi okuncoma. Kungale ndlela kuphela STYLECNC gqama phakathi kwezinhlobo eziningi ezithandwayo zokusika i-laser futhi uzuze ukuvunyelwa kwawo wonke umuntu.