2025 Umshini Wokuhlabathi Wezinkuni Ongcono Kakhulu we-CNC Othengiswayo

2025 Umshini wokugcwalisa ukhuni we-CNC ongcono kakhulu usetshenziselwa ukwenza isihlabathi nokupholisha ibhodi le-veneer, i-MDF, i-primer board, imikhiqizo yokhuni, i-WPC, futhi ungathenga ama-sander okhuni e-CNC athengiswa ngentengo yezindleko STYLECNC.

- Brand - STYLECNC

- imodeli - STS1300-IV

- Umenzi - I-Jinan Style Machinery Co,. Ltd.

- Usayizi weThebula - 1300mm x Okungenamkhawulo

- Amayunithi angama-360 esitokweni Atholakalayo Ukudayiswa Njalo Inyanga

- Ukuhlangabezana namazinga e-CE ngokwemigomo yekhwalithi nokuphepha

- Isiqinisekiso Esikhawulelwe Sonyaka owodwa Womshini Wonke (Iziqinisekiso Ezandisiwe Ziyatholakala Ezingxenyeni Ezinkulu)

- Isiqinisekiso Sokubuyiselwa Imali Sezinsuku Ezingu-30 Sokuthenga Kwakho

- Ukusekelwa Kwamahhala Kwempilo Yonke Kwabasebenzisi Bokugcina Nabathengisi

- Ku-inthanethi (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- I-Global Logistics kanye Nokuthumela Kwamazwe Ngamazwe Kuya Noma Kuphi

Yini i-CNC Wood Sanding Machine?

I-CNC wood sanding machine iwuhlobo lwethuluzi elizenzakalelayo lokusebenza ngokhuni elisebenzisa i-sand roller, i-pressure roller, kanye nesistimu yokuphakelayo ezenzakalelayo ukuze isihlabathi futhi ipholishe ubuso bephrojekthi yezinkuni. Yaziwa nangokuthi i-CNC wood sander, okuhloswe ngayo kakhulu embonini yokucubungula iphaneli lezinkuni, imboni yokulungisa amaphaneli aphansi nasodongeni, uqalo kanye nemboni yokucubungula yezandla yezinkuni, uqalo kanye namabhizinisi okucubungula amathoyizi okhuni. Inezici zokusebenza okulula, izinga eliphezulu lokuzenzekelayo, ukusebenza kahle kokukhiqiza okuphezulu, ubuchwepheshe obuvuthiwe nobuzinzile, kanye nezinsiza eziphelele ezisekelayo. Ingaxhunywa ngokuphelele nemishini ye-CNC ezenzakalelayo ukuze yakhe imigqa yokukhiqiza ezenzakalelayo ehlukahlukene.

Ukusandeni nokupholishwa amagama anomqondo ofanayo, futhi kokubili kubhekisela ekukhishweni ngokomzimba kwezinto kanye nezinto ezingalingani, ukujiya okungalingani, futhi ezingahlangabezani nezidingo zenqubo, ngendwangu ehuqayo, isondo lokugaya, i-sandpaper, i-couring pad, isondo lokupholisha elingalukiwe, njll. Libushelelezi futhi liyisicaba, futhi ukujiya kuyafana. Kuyindlela yokwenza ukuthi ifinyelele izinga. Isetshenziselwa ukukhiqizwa kwezinqubo ezihlukahlukene ze-veneer, ukukhiqizwa kwezingxenye ezijwayelekile zesakhiwo, imboni yezandla zamathoyizi, imboni yokuhlobisa kanye nefenisha, imboni yezinto zokwakha zephaneli yaphansi kanye nezindonga.

Njengoba igama lisho, i-sander iyithuluzi lomshini elisetshenziselwa ukuqedela umsebenzi we-sanding. Kubandakanya izinhlobonhlobo zezimboni futhi kunezinhlobo eziningi zezigaba. Nokho, abantu embonini ngokuvamile babiza le mishini enesimiso sokuphakela esizenzakalelayo ngokuthi i-sander, kanti eminye ibizwa ngemishini yokubopha amabhande, imishini yokugaya neyokupholisha.

Izici & Izinzuzo Zomshini Wokuhlabathi we-CNC Wezinkuni

1. Idizayini yesakhiwo somshini inengqondo, ilula futhi inhle, eyamukela inqubo yokusika i-brand laser ephezulu, i-workpiece 1st pickling rust, i-powder eyomile yokushisa iyunifomu yokugqoka.

2. Ijubane lokuphakela kanye nokuqina komshini we-sanding kungalungiseka ngokwanele.

3. Umklamo onengqondo: ukusebenza okuzimele kwekhabhinethi, ukusetshenziswa okulula nokugcinwa.

4. Umshini we-CNC unomsebenzi wokulungisa ukujiya, ongafinyelela ukuma okusheshayo kobukhulu bepuleti, kokubili ukukhiqizwa okunembile, kodwa futhi kuthuthukise kakhulu ukusebenza kahle kokukhiqiza.

5. Umshini we-sanding onekhwalithi ephezulu nokuzinza kulula ukuwulawula.

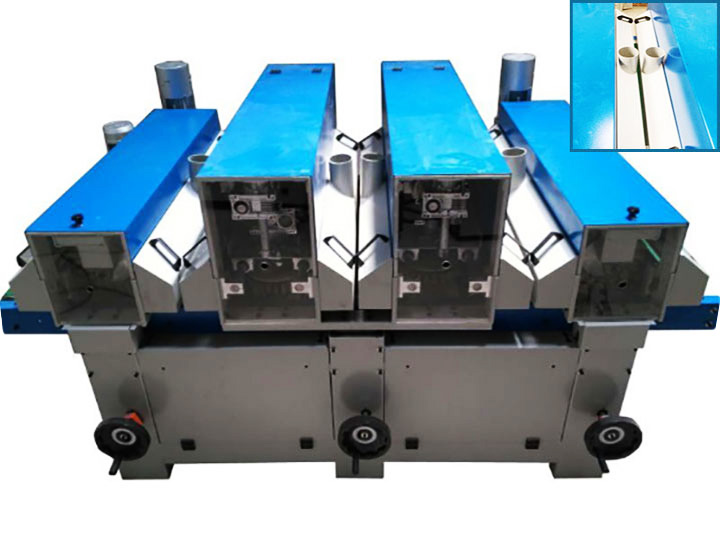

6. Umshini we-CNC uzothatha indawo yesihlabathi sobuciko bezandla zendabuko futhi ungakwazi ukusebenzisa ukupholisha emaceleni omabili aphezulu naphansi, okuthuthukise kakhulu ukusebenza kahle kokukhiqiza.

7. Imikhiqizo epholishwa umshini we-CNC ine-flatness enhle ebusweni, ilungiselela kahle ukugqoka okulandelayo.

Izicelo ze-CNC Wood Sanding Machine

CNC ukhuni sanding umshini kufanelekile flat noma ezimise olugobile ipuleti uhlobo, izinkuni line izinkuni isigaba, ezifana okuqinile ngokhuni iminyango, iminyango esiyinhlanganisela, izigaba imvelo, ekhishini umnyango panel, izinkuni flooring, amatafula nezihlalo panel, yokugezela ifenisha uchungechunge, kabanzi Veneer ibhodi, MDF, primer ibhodi, antique izinkuni iphethini ibhodi, imikhiqizo yokhuni, ukhuni (WPC) olungenasici ukugaya inqubo inhlawulo sanding.

I-CNC Wood Sanding Machine Imingcele Yezobuchwepheshe

| imodeli | I-ST-1300-IV |

| Isivinini sokusebenza | 10-1000mm |

| Ubukhulu bokusebenza | I-3—100mm |

| Ubude bokusebenza | ≥300mm |

| No.1 isivinini sokusebenza kwe-sand roller | 20m / s |

| No.2 isivinini sokusebenza kwe-sand roller | 20m / s |

| No.3 isivinini sokusebenza kwe-sand roller | 20m / s |

| No.4 isivinini sokusebenza kwe-sand roller | 20m / s |

| Kulayishwa isivinini | I-5—15m/ Iminithi |

| Ibanga eliguquguqukayo ledijithali eliguquguqukayo | 30—60ft/min |

| Amandla emoto aphelele | 6.2KW |

| voltage Ukusebenza | 380v50Hz |

| machine dimension | 2800x1700x1400 |

| isisindo machine | 1500kg |

| Vacuum isivinini somoya | 25-30m / s |

CNC Wood Sanding Machine Imininingwane

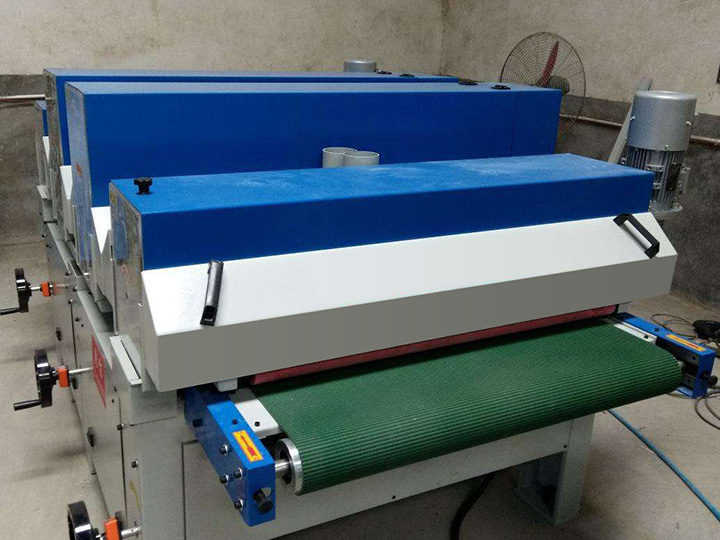

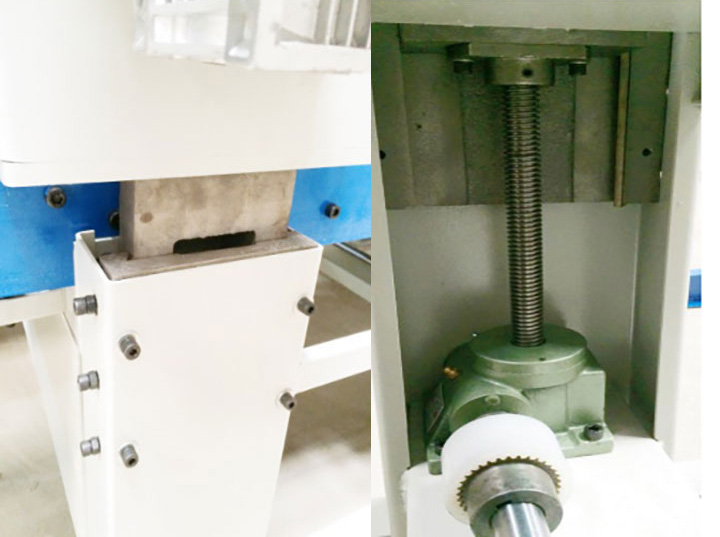

Ukunyakaza kwe-sand roller: Kuthatha i-dovetail slider lift ezimele, ukunemba kokuphakamisa, ukuzinza kanye namandla. I-sand roller ngayinye ingaba ukulungiswa kokuphakamisa okuzimele. I-workpiece ngeke ivele ngesikhathi esifanayo isisindo sesihlabathi, isimo sokukhanya kwesihlabathi.

I-pressure roller: ama-roller amaningi okucindezela, aminyene, nama-sand roller ngesikhathi esifanayo ukunyakaza. Igebe elincane le-roller, lingapholisha ipuleti lamasayizi ahlukahlukene. Kunganciphisa isikhathi sokulungisa imishini, ukonga isikhathi.

Ibhande: Ibhande lotshani elivundlile, indawo enhle ye-convexo-concave, yandisa ukungqubuzana, i-workpiece akulula ukushelela ngokukhululeka.

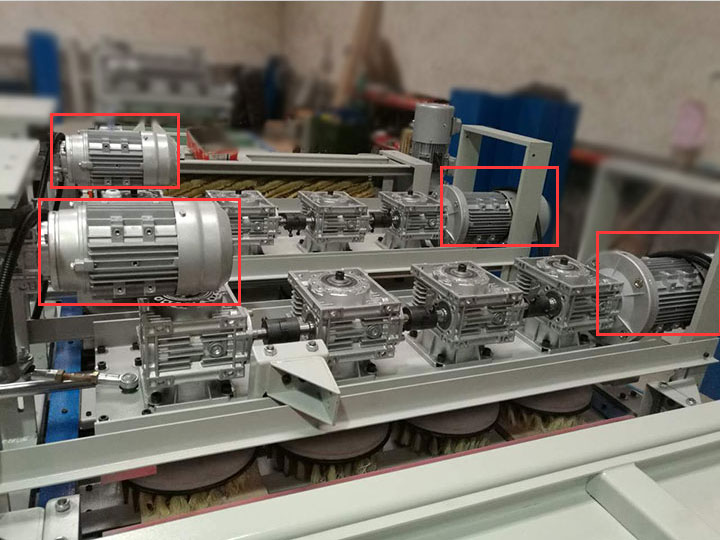

I-Sand roller motor: isilawuli semoto esishintshashintshayo esizimele, 1:7.5 isinciphisi segiya lezikelemu, idrayivu yokuhlanganisa insimbi, umphumela wokudlulisa, umfaniswano wesihlabathi, isivinini esishintshwayo, esizinzile.

I-Sand roller eguquguqukayo: iqondile, i-spiral, isihlabathi se-disc, i-sand roll ingashintshaniswa ngokungenasisekelo, ungakhipha ukuze uthole i-sandpaper, i-sisal noma i-Du Pont Russell inokuguquguquka kokuvikela ipuleti. Kulula ukushintshanisa ama-sand roller ahlukene, konga isikhathi, kulula ukushintsha i-sandpaper, ukwenza izinhlanga ezimhlophe, ukulungisa i-primer kalula, ukonga isikhathi nomzamo.

Vacuum: ama-sand rollers ayeyi-vacuum ezimele, umphumela muhle.

Zingaki Izinhlobo ze-CNC Wood Sanders?

Kunezinhlobo ezi-4 ezijwayelekile zemishini yokusanta: imishini yokusanding evamile, imishini yokusanta esindayo, imishini yokusanding engaphezulu, kanye nemishini yokusanding ezinhlangothini ezimbili.

USander ojwayelekile

Amandla okumisa umshini ovamile wokugcotshwa kwesihlabathi mancane, ifreyimu ilula ngokuqhathaniswa, imodeli incane futhi ilula, amandla esihlabathi e-sand roller mancane uma kuqhathaniswa, futhi kulula ukulinyazwa ngokusebenza kokugcwala ngokweqile, kodwa intengo iphansi ngokuqhathaniswa, ifanele ukusetshenziswa kokukhiqiza okuncane.

I-Heavy Duty Sander

I-sander-duty-duty ifakwe amandla aphezulu, uhlaka olusindayo, imodeli enkulu futhi esindayo, i-sanding roller enkulu, amandla amakhulu esihlabathi, aqinile futhi ahlala isikhathi eside, kodwa intengo imayelana 30% ephakeme kunaleyo yohlobo olujwayelekile, olufanele ukukhiqizwa nokusetshenziswa kwezinga elikhulu.

Okuphezulu Sander

I-overhead sander iyi-sander ethuthukisiwe futhi ekhiqizwe ukukhishwa kwesihlabathi onqenqemeni lwebhodi ngesisekelo se-sander esindayo. I-h8 ephakamisayo yetafula lokusebenza ingalungiswa phakathi kwebanga lika-0-650MM, futhi ububanzi bokuphakamisa umshini owenziwe ngokwezifiso bunganyuswa ngaphezu kwemitha eyi-1.

I-Double Sided Sander

Umshini we-sanding ohlanganisa izinhlangothi zombili ngesikhathi esisodwa unesakhiwo esiyinkimbinkimbi, ukulungiswa okungalungile kanye nezindleko eziphakeme, futhi usetshenziswa kuphela amabhizinisi amakhulu okucubungula insimbi.

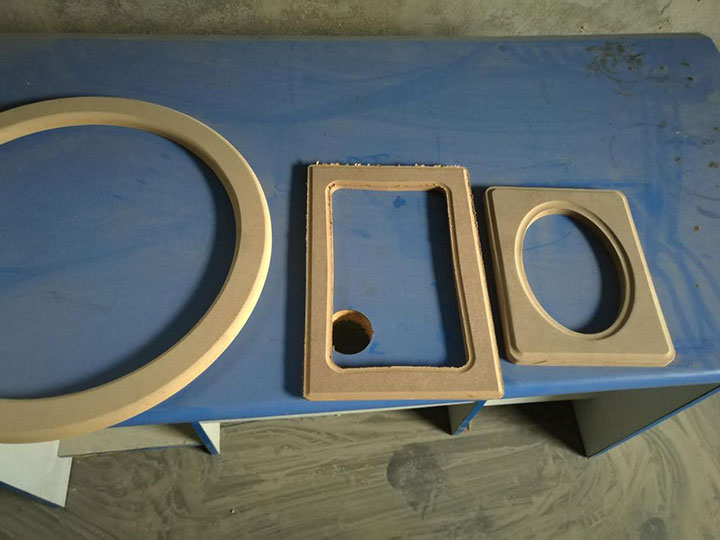

Amaphrojekthi we-CNC Wood Sander

I-Safe Operating Procedure (SOP)

1. Umsebenzisi kufanele ajwayelene nezixwayiso zokusebenza, ukusetshenziswa kanye nokusebenza komshini ngaphambi kokusebenza. Akuvunyelwe ngokuphelele ukuthi abaqalayo basebenzise umshini bodwa, futhi izisebenzi ezingahlobene nazo azivunyelwe ukusondela emshinini.

2. Umsebenzisi akufanele agqoke izingubo ezithinteka kalula emshinini (njengamathayi, imigexo, izingubo ezixegayo, njll.). Kulabo abanezinwele ezinde, sicela ugobe izinwele zakho, udonse phezulu noma ugqoke i-hood, futhi kwenqatshelwe ngokuphelele ukugqoka amagilavu ukuze usebenzise umshini.

3. Ungawuqaqeli umshini wokuphepha emshinini wokuhlanganisa isihlabathi ngokuthanda kwakho, futhi ungabeki noma yiziphi izinto ezingezona ezokusebenza ebhentshini lokusebenza, njengezikrufu, ukuze uvimbele izinto zangaphandle ukuthi zingabhajwa futhi zidale umonakalo emshinini.

4. Ngaphambi kokuvula iswishi yamandla, qiniseka ukuthi uyaqinisekisa ukuthi wonke amaswishi asesimweni sokuVALIWE. Ngaphambi kokusebenza okuvamile, hlola ukuhlanzeka nobukhali bebhande elihuzukayo, futhi uhlole ukuthi indlela yokufaka ibhande elilumayo ilungile yini (umcibisholo ongemuva kwebhande elilumayo ukhomba ohlangothini olufanayo nesondo lenjoloba) , Ukuthi ukucaciswa kwebhande elilumayo kufanelekile, noma ukushwibeka kwebhande kumaphakathi, noma ngabe ibhande eligijimayo liyi-converate, noma ngabe i-converate i-converate, noma ngabe ibhande eligijimayo liyi-converate. ibhande liqinile ngokulingene, nokuthi ngabe i-planer blade ifakwe kahle futhi iqinile yini.

5. Wonke amakhava okuzivikela akumele akhishwe ngaphambi kokucubungula. Kumele uqale unqume ukuthi usayizi wokhuni ungaphakathi kwebanga lokucubungula lomshini, futhi ulungise ubukhulu bokucubungula okulungile. Uma izinkuni ziwugqinsi kakhulu, ibhande lokuthutha lizonamathela futhi liphuke. Le mishini kuphela Ingasetshenziselwa ukhuni lwe-sanding olunokuqina komfaniswano. Angeke isetshenziselwe ukulungisa okuvundlile kokugoba ukhuni, futhi ukhuni oluwunxantathu, idayimane kanye ne-arc alukwazi ukucutshungulwa. Qinisekisa ukuthi unake i-workpiece ngaphandle kwensimbi nezinye izesekeli ukuze ugweme ukulimala komshini.

6. Ngesikhathi sokusebenza okujwayelekile, sicela unake umthwalo kagesi we-ammeter nganoma yisiphi isikhathi ukuvimbela umshini ukuthi ungakhubeki noma i-sandpaper ikhungathekile ngenxa yokugcwala komshini, okuholela ekuqhekekeni noma ekuqhekekeni kwebhande eliqhumayo. Indlela yokulungisa: 1. Yehlisa isivinini sebhande lesihlabathi; 2. Faka esikhundleni se-sandpaper ngegrit eqinile; 3. Phakamisa indawo yesondo lerabha noma i-sanding platen ukuze unciphise inani le-sanding.

7. Uma opharetha esebenza, lapho i-workpiece ibekwe ebhandeni lokuthutha, izandla zakhe kufanele zihambe ngokushesha, futhi i-workpiece kufanele ibekwe ngokulinganayo ebhandeni lokuhambisa, ukuze ibhande eliqhumayo kanye nesondo lenjoloba kugcizelelwe ngokulinganayo ukuze ugweme ukuguga okuhlangene futhi unciphise isikhathi phakathi kwebhande elibi kanye nesondo lenjoloba. Impilo esebenzayo.

8. Sebenzisa isilawuli sokuphakamisa idijithali sekhompiyutha ukuze ulungise ingaphezulu lomshini wesihlabathi. Ukulungiswa kwethebula kuvinjelwe ngokuqinile ngale kobubanzi bokulungisa besilawuli. Akuvunyelwe ukulungisa mathupha i-h8 yetafula ngaphandle kwemvume, ukuze kungabangeli ukuthi itafula litshekiswe noma idatha yesilawuli esiphakamisayo ibe nephutha. Ijubane lebhande lokudlulisa liyashintshashintsha ngokungenamkhawulo. Ukulungiswa, ijubane kufanele lilungiswe ngenkathi umshini usebenza.

9. Ngemuva kokuthi umsebenzi usuphelile, sicela uqiniseke ukuthi uhlanza ingaphakathi lomshini. Lapho uhlanza ingaphakathi, qiniseka ukuthi ususa i-sandpaper. Lapho ukuhlanza sekuqediwe, buyisela i-sandpaper. Kunconywa ukukhulula ibhande elihlabayo ngemva kokuba umsebenzi usuqediwe ukuze ugweme ukuphumula kancane kancane kwebhande elihlukumezayo ngenxa yokucindezeleka isikhathi eside.

10. Izisebenzi ezintsha kufanele ziqeqeshwe ngaphambi kokuba zisebenzise umshini, futhi ngaphambi kokuba isisebenzi sikujwayele ngokugcwele ukusebenza komshini, kufanele siphelezelwe isisebenzi esidala, futhi singasebenzi sodwa. Uma umqhubi efuna ukushiya isikhundla ngenxa yokuthile, kufanele aqale avale umshini, ukuze agweme ukuxoxa nabanye ngesikhathi sokuhlinzwa.

Ukuxazulula

Ngesikhathi sokusebenza komshini, amanye amaphutha avame ukwenzeka, kodwa lokhu kufanele kuqedwe ngesikhathi, kodwa uma kusingathwa ngendlela engafanele, kungase kuthinte ukukhiqiza nokwandisa izindleko. Lokhu kudinga opharetha ukuthi ajwayelane nemithethonqubo yokusebenza, ukusebenza okunekhono, nokuqedwa ngesikhathi. Amanye amaphutha awabi kakhulu uma etholwa, kodwa uma engasingathwanga ngendlela efanele, azodala amaphutha amakhulu futhi aphazamise ukukhiqiza. Okulandelayo ukuhlaziya amaphutha avamile emishini yokugaya izinkuni ye-CNC.

⒈ Ukuchezuka kwebhande ngokuvamile kubangelwa ukulungiswa okungalungile. Ukushwibeka kwebhande okujwayelekile kufanele kube yi-15-20mm ekujikeni, izikhathi ezingu-15-20 ngomzuzu ekuvaleni kokushwiba, isivinini esimaphakathi sokushwiba kanye nesivinini sokushwiba esingaguquki. Uma isesimweni esingavamile, isikhathi eside, ukuchezuka kungase kwenzeke, ikakhulukazi uma isivinini sokushwibeka nokuphuma singahambisani, maningi amathuba okuba kubangele ukuvala shaqa okungavamile; i-switch photoelectric yonakalisiwe, i-valve ye-solenoid yonakalisiwe, futhi isilinda sokuguqula sonakalisiwe. Ukuqoqwa kothuli olubi kanye nokugxilwa kothuli oluphezulu kuzothinta ukusebenza okuvamile kwe-photocell, futhi kubangele ukuba ibhande liphambuke; izesekeli ezilimele kufanele zishintshwe ngesikhathi ukuze kuthuthukiswe umphumela wokukhipha uthuli.

⒉ Ukuhluleka komkhawulo, kukhona ukushintsha komkhawulo kuzo zombili izinhlangothi zebhande elihuzukayo. Lapho ibhande eliqhumayo liphuma ekuhlelekeni futhi liphambukela ohlangothini olulodwa, thinta inkinobho yokulinganisa, ibhande eliqhumayo liyakhululwa, futhi injini eyinhloko imisa ngokuzenzakalelayo, engavikela ngempumelelo ibhande elilumayo. Uma umkhawulo wehlulekile, ungabangela umonakalo ebhandeni eliqhumayo, izinhlansi ezivela kuhlaka lwefriction, ngisho nomlilo. Ngakho-ke, ukushintshwa komkhawulo kufanele njalo kuhlole ukuthi isenzo sithembekile yini.

3. Ibhande elilumayo lishwabene. Uma ibhande elilumayo selishwabene, ngeke lisasetshenziswa. Ngokuvamile, kunamathuba angu-3 okushwabana kwebhande elilumayo: okubangelwa ukugqoka kwe-roller abrasive kanye ne-tension roller, ukugaya nokulungisa i-roller; Ingelashwa ngokomiswa nokomiswa; ubuso be-sand roller bugqwalile futhi bubuhlungu uma i-sander ingasetshenziswa isikhathi eside, futhi ukujikijela kwebhande kunzima ukudala ukuthambekela. Ngalesi sikhathi, i-roller kufanele ichithwe noma iphuculwe nge-sandpaper ecolekile.

⒋Ukuphuka kwebhande elihuzukayo kanye nokuphuka kwebhande elihuzukayo ngokuyinhloko kubangelwe ukuchezuka kwebhande elihuzukayo, noma ibhande elicibilikile alishintshwa ngesikhathi, noma umthwalo wesihlabathi mkhulu kakhulu, noma into eqinile ihlangatshezwana nayo phakathi nenqubo yokugcotshwa kwesihlabathi, noma ikhwalithi yebhande eliqhumayo ibangelwa ngokwalo. Ibhande le-abrasive kufanele ligwenywe ngangokunokwenzeka, ngaphandle kwalokho lingabangela umlilo. Uma i-current ingavamile, kufanele kubhekwe ukuthi ibhande eliqhumayo liye laba buthuntu, futhi uma kunjalo, kufanele lishintshwe ngesikhathi.

5. Ekulungiseni umshini we-sanding, kuyadingeka ukulungisa i-back pressure spring ye-roller edlulisayo ephezulu ibe yi-2-thirds (eyodwa yesi-3 esele), futhi isikhawu phakathi kwe-roller yokudlulisa ephezulu kanye ne-roller yokudlulisa ephansi kufanele ilingane Ubukhulu be-slab edlulile bungaphansi kuka-1.5mm or 1mm, uma kungenjalo kuzobangela ukuthi i-slab ichezuke noma ishelele. Ezimweni ezimbi kakhulu, kuzodala ukuphindaphinda, okungalimaza ukuphepha komuntu siqu.

6. Ubukhulu bepuleti lesihlabathi liyashintsha ngemva kokushintshwa kwebhande eliqhumayo, futhi indawo ye-cantilever yomshini wokuthulula ishintshashintsha kakhulu lapho ibhulokhi yokukhiya ixegiswa noma ikhiyiwe, okufanele ngokuvamile ibe ngaphakathi. 0.5mm. Uma likhulu kakhulu, lapho ibhulokhi yokukhiya ikhiya i-cantilever, umehluko emandleni okukhiya uzodala umehluko ekuphindaphindeni kwe-cantilever, okubangela ukuthi ubukhulu bepuleti le-sanding liguquguquke, okuthinta ngokuqondile ukunemba kwesihlabathi se-sander. Uma iphutha le-cantilever likhulu kakhulu (ngaphezu koku 0.5mm), ama-bolts okulungisa we-block locking kufanele akhululwe futhi alungiswe kahle. Ngesikhathi esifanayo, lapho ibhande le-abrasive lishintshwa, amandla okukhiya we-block locking kufanele afane.

7. Uma irola elidlulisayo lizungeza ngezikhathi ezithile noma lingajikijeli lapho imoto ingenalutho, isimo esingenhla asikwazi ukubonwa ngokuvamile. Ingatholakala kuphela uma imoto ingenalutho. Isizathu ukuthi igiya lezikelemu ligqokwa ngokwengxenye noma ngokuphelele ngesikhathi sokuncipha kwegiya lezikelemu elihambisa amandla. Nakuba kungeke kuphazamise umsebenzi, amanye amagiya ezikelemu azofinyeza impilo futhi abangele ukulahlekelwa okukhulu ngenxa yokwanda komsebenzi. Ngakho-ke, ngokushesha lapho lesi simo sitholakala, kufanele sishintshwe ngokushesha.

8. Ukudlidliza okungavamile kwesihlalo sokuthwala esikhulu. Ngaphansi kwezimo ezijwayelekile, ukudlidliza kwesihlalo esinesihlalo esikhulu kuncane kakhulu, futhi u-opharetha onolwazi angahlulela ukuthi kujwayelekile yini ngokusithinta. Ngokuvamile, asikho isimo sokuyilinganisa ngensimbi esizeni, kodwa ingahlulelwa ngokuyiqhathanisa nezinye izihlalo ezithwele, noma ingahlulelwa ebusweni bebhodi lesanding. kubi ukwahlulela. Uma kunokudlidliza okungavamile kwesihlalo esithwalayo, kungacatshangwa ukuthi kunezizathu ezi-2. Enye ukuthi i-bearing yonakalisiwe, inqobo nje uma i-bearing ishintshwa, enye iwukuthi i-roller yokuxhumana igugile futhi ilahlekile, futhi ibhalansi yasekuqaleni eguquguqukayo iyabhujiswa, okuholela ekudlidlizeni okungavamile. Lesi simo kufanele kube Susa ama-sand rollers ukuze asebenze.

9. Ibhande elikhulu lokushayela liyashelela. Kwezinye izinhlobo zama-sanders, amabhande ayisicaba ahamba ngesivinini esiphezulu asetshenziswa. Leli fomu lokudlulisela lisebenza kahle kakhulu kune-V-belt transmission. Kodwa-ke, ekusetshenzisweni kwangempela, kuzoba nokuphambuka kwebhande noma ukushelela, okubangelwa ikakhulukazi ukulungiswa okungalungile. Kufanele ilungiswe ngokuhambisana ngokuqinile nezidingo zezinga lokwelulwa kwebhande lika-1.5-2%, futhi ukuqina kwezinhlangothi zombili zebhande kufanele kuhambisane. Ngemuva kokuthi ukulungiswa sekuqediwe ngokuya ngezidingo, umsebenzi wesilingo kufanele wenziwe, ikakhulukazi lapho i-current motor main ikhuphuka ngokuzumayo, bheka ukuthi ibhande liyaphambuka.