I-Automatic Smart 3D Irobhothi Le-Industrial Laser Welding Iyathengiswa

Ingabe ufuna irobhothi lokushisela i-laser elizenzakalelayo lokwenza imoto, ukukhiqizwa kwe-aerospace, ukwakha umkhumbi, i-kitchenware, ukwenza isikhunta namanye amapulani namaphrojekthi okukhiqiza izimboni? Thola yonke imishini yokushisela ehambisana nesabelomali engu-6 axis industrial robotic fibre laser beam welder 2025 ehambisana nezingalo zamarobhothi ahlakaniphile, futhi uthenge okungcono kakhulu 3D irobhothi le-laser welding yezimboni ngentengo yezindleko ezivela kubakhiqizi abadumile nemikhiqizo. I LWRI-3000 ingahlangabezana nazo zonke izidingo zakho zokushisela, kusukela 3D ukushisela ibhizinisi elincane ukuhlanganiswa komugqa wokukhiqiza kubakhiqizi bezimboni ezinkulu.

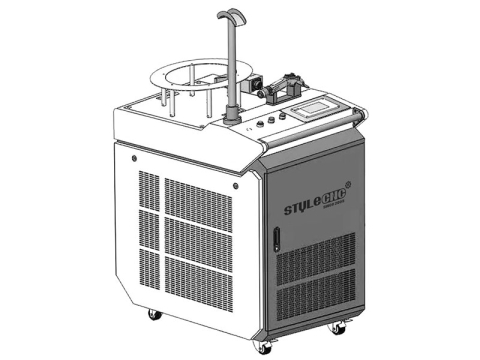

- Brand - STYLECNC

- imodeli - LWR3000

- Umthombo we-Laser - Raycus, IPG, MAX

- Option Power - 1500W, 2000W, 3000W, 6000W

- Amayunithi angama-320 esitokweni Atholakalayo Ukudayiswa Njalo Inyanga

- Ukuhlangabezana namazinga e-CE ngokwemigomo yekhwalithi nokuphepha

- Isiqinisekiso Esikhawulelwe Sonyaka owodwa Womshini Wonke (Iziqinisekiso Ezandisiwe Ziyatholakala Ezingxenyeni Ezinkulu)

- Isiqinisekiso Sokubuyiselwa Imali Sezinsuku Ezingu-30 Sokuthenga Kwakho

- Ukusekelwa Kwamahhala Kwempilo Yonke Kwabasebenzisi Bokugcina Nabathengisi

- Ku-inthanethi (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- I-Global Logistics kanye Nokuthumela Kwamazwe Ngamazwe Kuya Noma Kuphi

Iyini i-Laser Welding Robot?

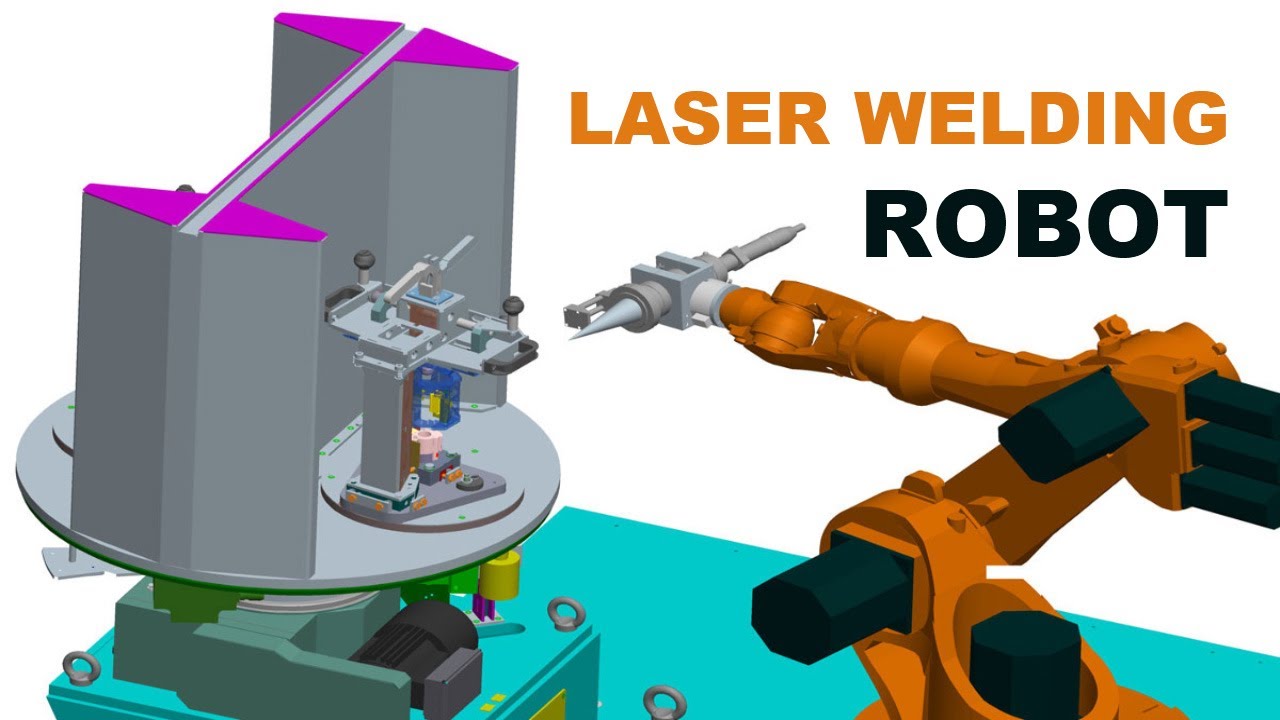

Irobhothi elenziwe nge-laser liyinhlanganisela yobuchwepheshe be-laser namarobhothi. Uhlelo lwamarobhothi we-laser welding iyirobhothi eyi-axis eyi-6 eguquguqukayo ephezulu, engaqedela ukushisela ama-workpieces ayinkimbinkimbi, futhi ingakwazi ukuzivumelanisa nezimo ezishintshayo ze-workpieces. Uhlelo lwe-laser lungasebenzisa amalensi okushisela, amalensi okusika, amalensi wokushisela ama-lens ngisho namakhanda okuvala i-laser. Ngenxa yendlela yokuxhumanisa kazibuthe, amalensi ahlukene angashintshwa ngokushesha aqondane. Irobhothi lokushisela i-laser yaziwa nangokuthi umshini wokushisela we-robotic laser, i-robotic laser welder, irobhothi le-laser beam welding, i-laser beam welding iwuhlobo olugcwele lwe-LBM, ngakho-ke ungalibiza nangokuthi irobhothi le-LBW.

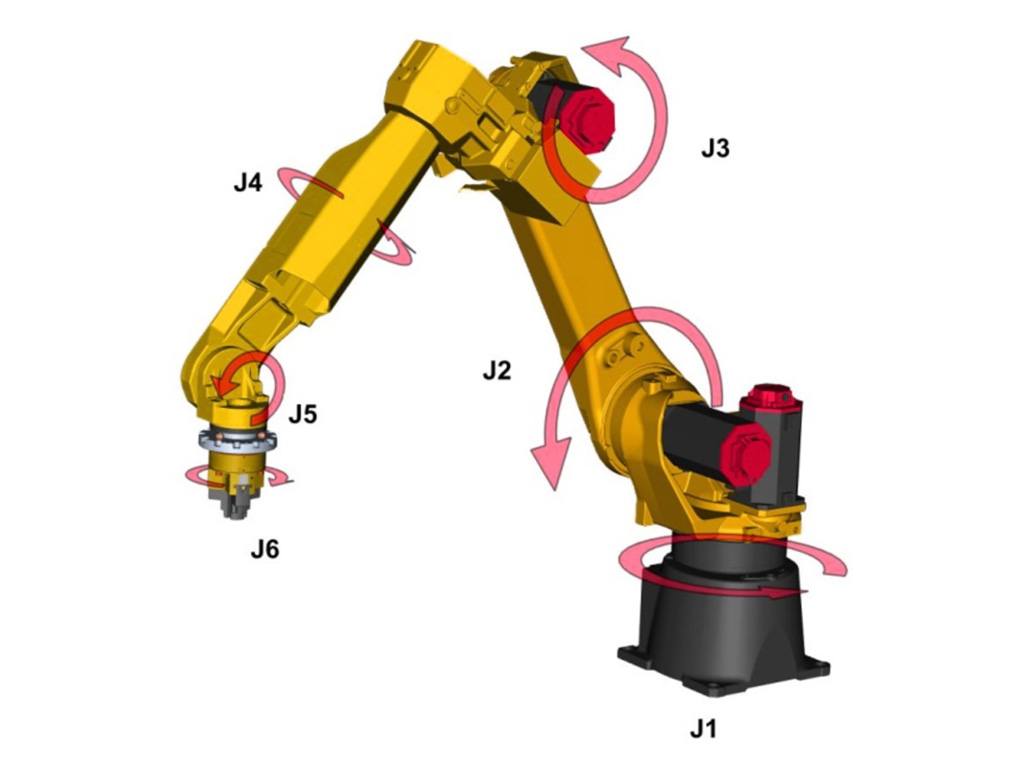

Irobhothi lokushisela lakhiwe izingxenye ezi-3 eziyisisekelo: umshini, isistimu yokushayela kanye nesistimu yokulawula. Umshini uyisisekelo kanye ne-actuator, kanti amanye amarobhothi nawo anomshini wokuhamba. Amarobhothi amaningi ashiselayo anokunyakaza okungu-3 kuya ku-6, lapho isihlakala ngokuvamile sinokunyakaza okungu-1 kuya ku-3. Isistimu yokushayela ihlanganisa idivayisi yamandla kanye nendlela yokudlulisela ukwenza i-actuator ikhiqize izenzo ezihambisanayo. Uhlelo lokulawula luthumela amasiginali womyalo ohlelweni lokushayela kanye nama-actuator ngokohlelo lokufaka, futhi luyawalawula.

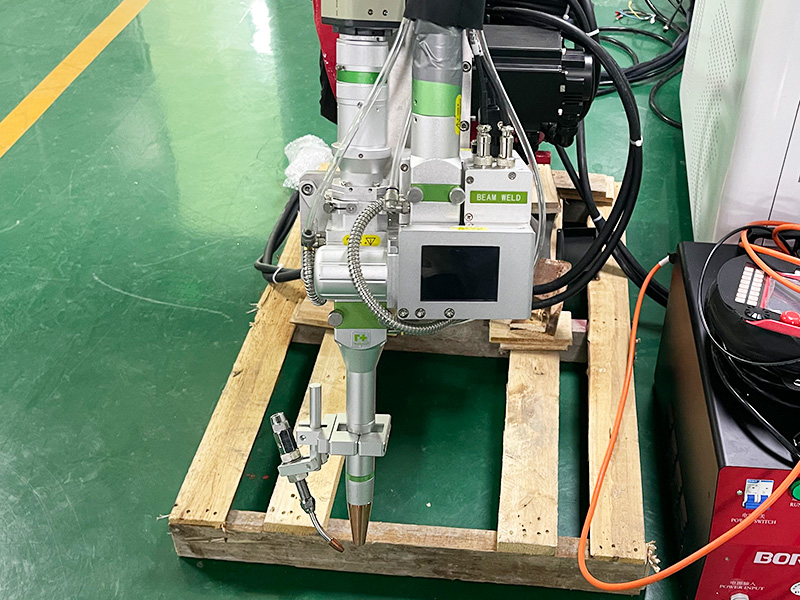

Ukuze ujwayelane nerobhothi lokushisela i-laser ngezinjongo ezihlukene, ukusebenzelana komshini kwe-eksisi engemuva kwerobhothi kuvame ukuba i-flange exhumayo, engaxhunywa kumathuluzi ahlukene noma iziphetho. Amarobhothi okushisela i-laser beam anamathisela izindlawu zokushisela noma izibhamu zokushisela (zokusika) endaweni yokugcina ye-shaft flange yamarobhothi ezimboni ukuze akwazi ukushisela, ukusika noma ukufafaza okushisayo.

Imingcele Yezobuchwepheshe ye 3D I-Industrial Fiber Laser Welding Robot

| imodeli | LWR1500 / LWR2000 / LWR3000 / LWR6000 |

| Amandla e-Laser | 1500W / 2000W / 3000W / 6000W |

| Phinda Ukunemba Kokumisa | ±0.05mm |

| I-Technical Wingspan (mm) | 1800mm |

| Ukufakwa kwamapharamitha | Isitezi Sokumisa / Hlala Ubheke Phansi |

| Kukalwe Umthwalo | 20kg |

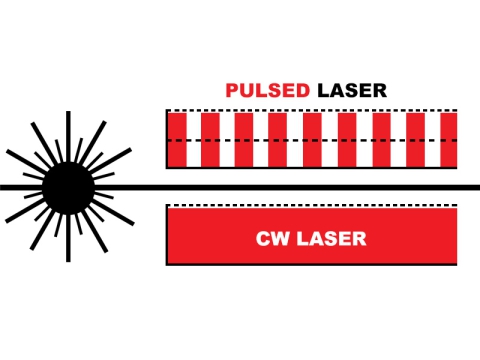

| Imodi yokusebenza ye-Laser | CW |

| I-Laser WaveLength | 1080nm |

| Ikhanda Lensimbi | Ama-Raytools |

Izici & Izinzuzo ze 3D I-Industrial Fiber Laser Welding Robot

Umshini wokushisela we-robotic laser wuhlobo lwe 3D irobhothi lezimboni elisetshenziswa kakhulu namuhla. Inokunemba okuphezulu kwe-welding, isivinini esikhulu, kanye ne-welding seam emincane, edume kakhulu emkhakheni we-welding.

Njengoba sonke sazi, imisebenzi yokushisela yendabuko iyingozi kakhulu emzimbeni womuntu, okuhlanganisa ukushisela kwe-MIG (Metal Inert Gas) kanye ne-TIG (Tungsten Inert Gas) yokushisela. I-MIG welder kanye ne-TIG welder yi-arc welding, futhi ikhwalithi yephrojekthi ye-laser-welded ayikwazi ukuqinisekiswa. Amabhizinisi amaningi aqala ukusebenzisa amarobhothi e-laser welding asebenza kahle kakhulu esikhundleni sokusebenzisa imisebenzi yokushisela. I-robotic laser welder inekhono eliphezulu lokukhiqiza, amandla aphezulu okushisela, umthungo omncane wokushisela, kanye nokuguqulwa okuncane kwesiqeshana sokusebenza. Namuhla, ake sikhulume ngezinzuzo zamarobhothi wokushisela.

Ngokungafani nenqubo yamanje yokushisela indawo, i-laser beam welding ingafinyelela ukuhlangana kwamangqamuzana phakathi kwamapuleti ensimbi amabili. Ngokuvamile, ukuqina kwepuleti lensimbi elishiselwe kulingana ne-steel plate yonke, ngaleyo ndlela kukhulisa amandla omzimba 30% kanye nokunemba komzimba Okufanayo kuthuthukiswa kakhulu. Yiqiniso, ukubaluleka okungokoqobo kwe-laser welding akugcini lapho. Ngokuvamile, amaqhuqhuva asuka phansi lapho imoto ihamba emgwaqeni azoguqulwa abe izinkulungwane zokusonta ngomzuzu ukuze kuhlolwe umzimba. Uma ukunemba kwenhlanganisela yomzimba namandla kunganele, imvamisa engavamile nomsindo emotweni kuzoba njalo, futhi kungase kube bucayi. Lokhu kungadala umonakalo ezingxenyeni ezifakwe emotweni, njengo-gearbox, ama-asi angaphambili nangemuva, noma ukuphuka komzimba.

I-FANUC Robot Arms noma i-Chinese Borunte Robot Arms

Irobhothi lezimboni le-FANUC laseMelika, ukunemba kokuma okuphezulu, uhla olukhulu lokushisela, kanye nokuxhumana kwe-axis eyi-6 ukuze kutholakale ukushiselwa 3D izingxenye.

Raytools Laser Welding Head

Ikhanda le-laser welding lisebenzisa amamotho amabili, linezinhlobo ezahlukene zokushwibeka, futhi lilungele uhla olubanzi lwezimo.

Raycus Laser Umthombo Welding

• Ukusebenza kahle kwe-Electro-optic Conversion.

• Ukuthembeka okuphezulu, impilo ende yesevisi.

• Ukusebenza Kwamahhala.

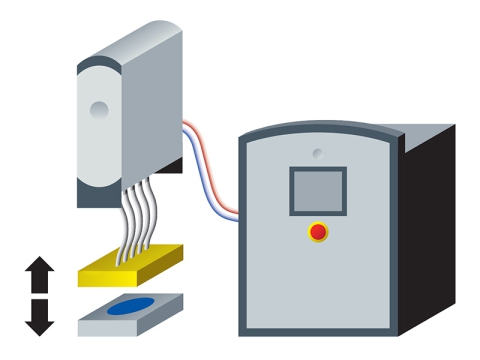

I-Water Chiller ye-Laser Welding

• Umsebenzi wokupholisa kabili.

• I-alamu yesikhathi sangempela.

• Ukuvikelwa komshini.

I-laser welding ibonakala ngokuguqulwa okuncane kakhulu kwe-workpiece eshiselwe, cishe alikho igebe lokuxhuma, kanye nesilinganiso sokujula / ububanzi bokushisela, ngakho izinga lokushisela liphakeme kunezindlela zendabuko zokushisela. Ngokucutshungulwa kwekhompiyutha ye-elekthronikhi, ngokuya ngezinto ezihlukene zokushisela kanye nezidingo, njengokulandela umthungo wokushisela, ukutholwa kwesici, ukuqapha ikhwalithi ye-welding namanye amaphrojekthi ayabonakala, kanye nemingcele yenqubo yokushisela iyalungiswa ngokulawulwa kwempendulo ukuze kubonakale ukushiselwa kwe-laser okuzenzakalelayo. Ngakho-ke, i-laser welding iyinqubo yokukhiqiza ethuthuke kakhulu kwezobuchwepheshe.

⇲ Amandla nosayizi wokugxilwa kwe-laser kungashintshwa ngokuguquguqukayo ngokuya ngezidingo zokucubungula, futhi inqubo yokucubungula ingaqashelwa ngesikhathi sangempela ukuze kuzuzwe amathuba ahlukahlukene okusebenza.

⇲ Indawo yomgodi incane, futhi ukunemba kokucubungula kuphindwe kabili. Indawo ethintekile ekushiseni incane kakhulu, ikhwalithi ye-weld iphezulu, futhi akulula ukukhiqiza ukuncipha, ukuguqulwa, i-embrittlement kanye nokuqhekeka okushisayo neminye imiphumela emibi eshisayo. I-laser welding ye-molten pool purification effect ingahlanza insimbi yokushisela, futhi izakhiwo zemishini ze-weld ziyalingana noma zingcono kunesisekelo sensimbi.

I-Fiber Laser Welding Robot Arm

⇲ Ukusetshenziswa kwe-fiber optical ukuthutha i-laser, ukuze umthombo wamandla nemishini yokucubungula kuhlukaniswe esikhaleni ngaphandle kobunzima. Amandla okukhanya akhiqizwe i-laser angadluliselwa esiteshini sebanga elide ngokusebenzisa i-fiber optical fiber encane, futhi ucezu lokusebenza lungashiselwa ngerobhothi.

⇲ Umshini wokushisela we-laser werobhothi ungashintsha amarobhothi angama-3 kuya kwangu-4. Uma usebenzisa ngokugcwele ubuchwepheshe bokushisela nge-laser ukucubungula indikimba yemoto, izindleko zokutshala imali ngamathuluzi, ukulungiswa kokushisela, ukusetshenziswa kwezinto ezibonakalayo, kanye nokuvala umzimba kuzoncishiswa cishe ngo-At. US$200, izinga lokusetshenziswa kwensimbi lingakhuphuka ngo 50%. Ukusetshenziswa komshini wokushisela we-laser we-robotic kungasindisa ama-prototypes amaningi kanye nemishini yamathuluzi, ukuze indawo yokusebenzela ihlukaniswe ngesigamu futhi kugcinwe ukutshalwa kwezimali.

Ukulungiswa Ngokwezifiso

Yenza ngokwezifiso izinto zokushisela ngokwezidingo zekhasimende ukuze uqinisekise ukunemba komshini we-workpiece.

Kuleli qophelo, wonke umuntu kufanele abe nokuqonda okujulile ngezinzuzo zamarobhothi we-laser welding. Irobhothi lingashintsha uhlelo nokufundisa ngokwemisebenzi ehlukene ukuze liqedele imisebenzi eminingi. Inciphisa kakhulu izindleko zokucubungula i-workpiece futhi iqinisekisa ukusebenza kahle kokukhiqiza kwamabhizinisi, ngakho-ke isetshenziswa kabanzi. Ngezidingo zokuthuthukiswa kwezimboni, Uhlelo lwe-robotic laser welding luzodala amathuba amaningi esintu esikhathini esizayo.

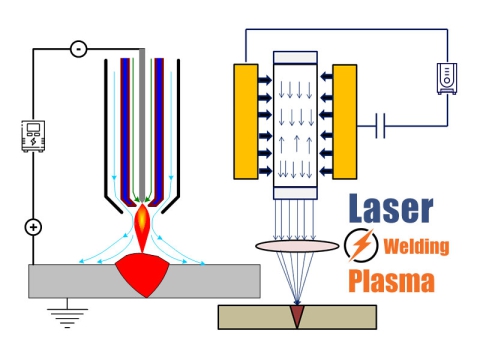

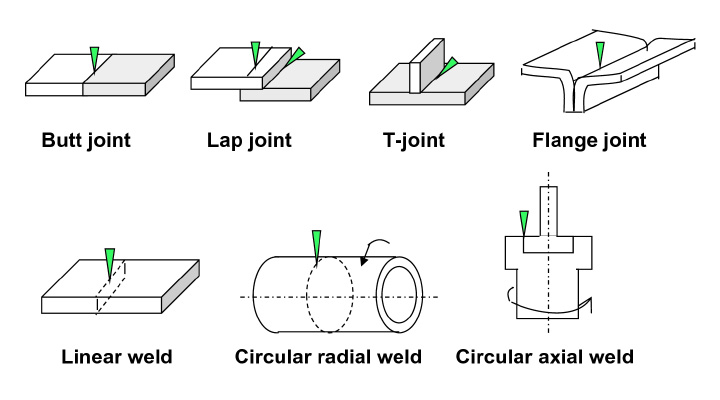

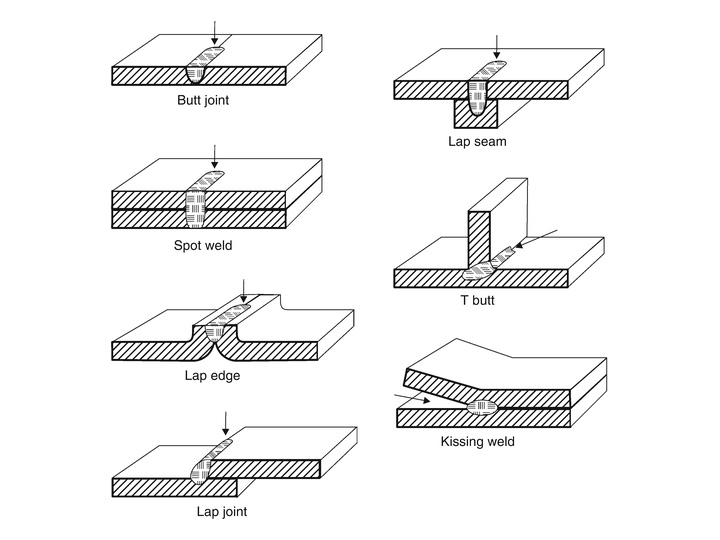

Izinhlobo ze-Laser Welding

3D I-Industrial Fiber Laser Welding Robot Applications

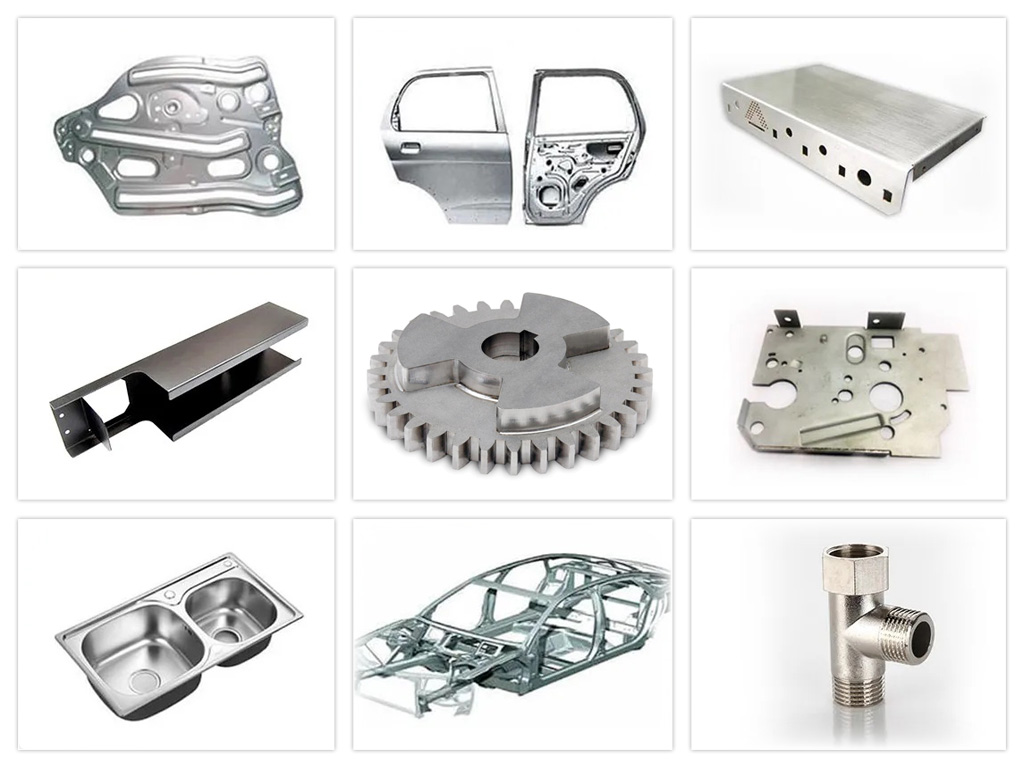

Amarobhothi okushisela nge-laser aya ngokuya ehlakanipha, futhi manje asephenduke imikhiqizo ephezulu emkhakheni wokushisela, futhi athandwa kakhulu embonini yokushisela ngokunemba. Ama-laser welding amarobhothi aklanyelwe ukushisela izinsimbi ezihlukahlukene kanye nezinto ze-alloy, futhi afanelekele ukushisela okunembayo kwezingxenye ezihlukahlukene zensimbi. Zisetshenziswe kakhulu ezimbonini ezisezingeni eliphezulu ezifana ne-instrumentation, imikhiqizo ye-electromechanical, imishini ye-aerospace, ukwakhiwa kwemikhumbi, kanye nokukhiqiza izimoto.

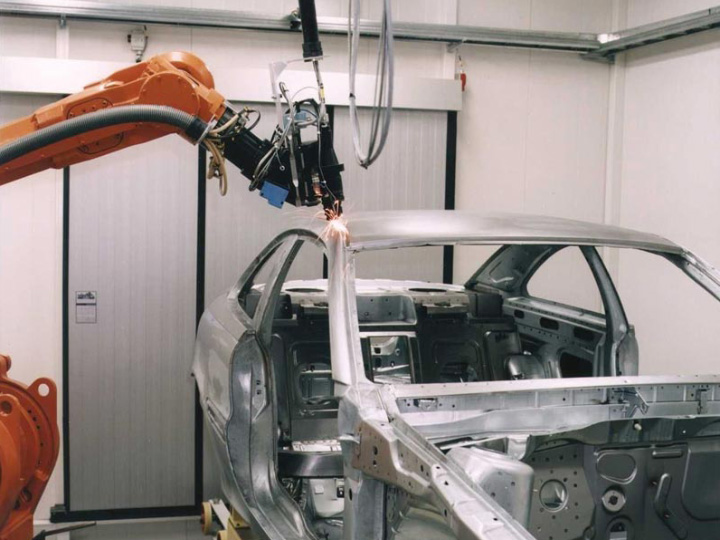

Ukukhiqizwa Kwezimoto

Amarobhothi we-laser welding asetshenziswe kabanzi embonini yokukhiqiza izimoto. Ukushiselwa kwe-chassis yezimoto, amafreyimu ezihlalo, ojantshi abaqondisayo, ama-muffler kanye neziguquli ze-torque sekusetshenziswe kabanzi, ikakhulukazi ekukhiqizeni ukushisela i-chassis yezimoto. KwaToyota banqume ukusebenzisa i-spot welding njengendlela yokuhlomisa wonke amarobhothi abo okushisela eJapan naphesheya kwezilwandle. Ukusebenzisa lobu buchwepheshe kungathuthukisa ikhwalithi yokushisela, ngakho-ke ngisho nokuzama ukubusebenzisa esikhundleni sokusebenza kwe-arc welding. Isikhathi sokunyakaza emabangeni amafushane naso sifinyezwa kakhulu. Le nkampani isanda kwethula irobhothi le-low-h8 spot welding, elisetshenziselwa ukushisela izingxenye ezingezansi zemoto. Leli robhothi lokushisela indawo emfushane lingahlanganiswa nerobhothi elide ukuze licubungule ngokuhlanganyela ingxenye engaphezulu yomzimba wemoto, ngaleyo ndlela kufinyezwe ubude bawo wonke umugqa wokukhiqiza wokushisela.

Aerospace Manufacturing

I-robotic laser welder isetshenziswa ezimbonini ezahlukahlukene ngenxa yokuphindaphindeka kwayo okuphezulu, ukwethembeka okuhle, nokusebenza okuqinile. Njengamanje, inqubo yokwenziwa kwemikhiqizo yasemkhathini isadinga abasebenzi abaningi, inkimbinkimbi yezinqubo, kanye nezimo ezimbi zokusebenza, okulekelelwa inani elikhulu lezinto ezisetshenziswayo kanye nokukhiqizwa kwezandla. Ukuntuleka kwamandla okukhiqiza okuzenzakalelayo sekuphenduke umgoqo ovimbela ukwenziwa ngcono kokwethembeka namandla okukhiqiza ezikhali namathuluzi. Ukusetshenziswa kwamarobhothi ezimboni emabhizinisini akhiqiza i-aerospace ukuze akhiqize ngokuzenzakalelayo kubaluleke kakhulu ekuguqulweni nasekuthuthukisweni kwamamodeli okukhiqiza amabhizinisi kanye nokwenza ngcono amakhono okukhiqiza imishini ethuthukisiwe. I-Welding iyisixhumanisi esibalulekile enqubweni yokukhiqiza imikhiqizo ye-aerospace. Indima yamarobhothi we-laser welding ibaluleke kakhulu.

I-Kitchenware

Ukusetshenziswa kwamarobhothi we-laser welding embonini ye-kitchenware sekuphenduke inkambiso yentuthuko. Abakhiqizi abaningi basebenzise amarobhothi okushisela i-laser beam ekwenzeni i-hardware kitchenware, ikakhulukazi ukushiselwa kwekhava yangaphandle ye-kitchenware enkulu njengama-hoods, osinki, namabhokisi okubhaka, okuthuthukise ukusebenza kahle kokukhiqiza futhi kwathola umphumela omuhle.

Ukuze kwenziwe i-kitchenware yensimbi engagqwali ibe yinhle kakhulu futhi ihlangabezane nezidingo ezihambisanayo zomphakathi, i-robotic laser welder isebenzisa amandla aphezulu aqhubekayo okushisela okungenamthungo ukuze kuzuzwe imiphumela engcono, ngaphandle kwanoma yikuphi okusebenzisekayo, kanye nokusebenza okulula nokulula. I-laser welding inezici zejubane lokushisela elisheshayo, ukuwohloka okuncane kwendawo yokusebenza, isilinganiso esikhulu se-weld fusion, usayizi wokusanhlamvu ocolekile, ukucubungula okulula kwe-post-weld, kanye nekhwalithi enhle yokushisela. Ingakwazi ukushisela izinto ezifanayo noma ezihlukene noma izinto eziphikisayo ezindaweni ezihlukahlukene.

Kuzinto zokwakha ze-kitchenware ezishumekiwe, ngokwakhiwa kwensimbi engagqwali eyingqimba ephindwe kabili, umkhiqizo ngokwawo uthuthukise imiphumela yokulwa nokuwa kanye ne-anti-corrosion. Ngaphezu kwalokho, ukwakheka kwensimbi engagqwali okuqinisiwe kumelana namazinga okushisa aphezulu kanye nomthelela kuneningi lezinto zikagesi zepulasitiki, ezingagcini nje ukwandisa isikhathi sokusetshenziswa komkhiqizo, kodwa futhi kuthuthukisa kakhulu ukuphepha kokusetshenziswa. Ekucubunguleni izitsha zasekhishini ezishunyekiwe, ukuze kuzuzwe imiphumela engcono yokushisela, izinkampani eziningi zemishini yasendlini zisebenzisa ubuchwepheshe be-laser welding.

Ubuchwepheshe be-robot laser welding bubanzi emakethe yokukhiqiza

Amazwe amakhulu emhlabeni anezimboni abheka ukubaluleka okukhulu endimeni yezikhungo zocwaningo zokushisela, futhi ngokuyisisekelo akha uhlelo olunamazinga ama-3 ocwaningo nokuthuthukiswa kwezikhungo zocwaningo zamanyuvesi namabhizinisi. Wonke amazwe amakhulu athuthukile ezimbonini asesungule izikhungo zocwaningo lokushisela, njengeBritish Welding Research Institute (TWI), American Edison Welding Research Institute (EWI), French Welding Research Institute (FWI), kanye neJapanese Connection and Welding Research Institute (JRWI), The Barton Electric Welding Institute (PEWI) yase-Ukraine, i-Welding Research Institute (ISF) yaseNyuvesi yase-Aachen kanye neSikhungo Sokucwaninga saseJalimane (DVS), njll. Isikhungo socwaningo sise-KITCH of Korea Institute of Industrial Production Technology (KAIST) ye-Korea Institute of Modern Science and Technology (KAIST). Wonke angaphansi kwezikhungo zocwaningo lwe-welding zikazwelonke.

3D I-Industrial Fiber Laser Welding Robot Projects & Plans

3D I-Industrial Fiber Laser Welding Robot ye-Car Body Welding

3D I-Fiber Laser Welding Robot ye-Auto Parts Welding

3D I-Laser Welding Robot ye-Kitchenware Welding

3D Irobhothi le-Industrial Laser Welding for Sheet Metal & Tube Welding Projects

Ikusasa le- 3D Irobhothi ye-Industrial Laser Welding

Izikhombisi-ndlela zocwaningo zesikhathi esizayo ze-robotic laser welding technology ikakhulukazi zihlanganisa:

⇲ Uhlelo lokulawula inqubo yokushisela ehlakaniphile. Ukuthuthukiswa kobuchwepheshe be-elekthronikhi, i-microelectronics yamakhompiyutha kanye nobuchwepheshe be-automation kukhuthaze ukuthuthukiswa kobuchwepheshe bokushisela. Ikakhulukazi, ukwethulwa kobuchwepheshe beyunithi njengobuchwepheshe bokulawula izinombolo, ubuchwepheshe bokukhiqiza obuvumelana nezimo kanye nobuchwepheshe bokucubungula ulwazi kukhuthaze ukuthuthukiswa kwenguquko yobuchwepheshe bokushisela;

⇲ Yenza ucwaningo ngezindlela ezingcono kakhulu zokulawula, kufaka phakathi izilawuli eziqondile nezingaqondile. Okumele kakhulu ukulawula okungaqondakali, ukulawulwa kwenethiwekhi ye-neural yenqubo yokushisela, kanye nocwaningo lohlelo lochwepheshe;

⇲ Ubuchwepheshe be-welding flexible. Hlanganisa ubuchwepheshe obuhlukahlukene be-optical, mechanical kanye nogesi nobuchwepheshe be-welding ukuze uzuze ukushisela okunembile nokuguquguqukayo. Ukusetshenziswa kobuchwepheshe be-microelectronics ukuguqula imishini yenqubo yokushisela kuyindlela eyisisekelo yokuthuthukisa izinga le-welding automation. Ifakwe imishini yokushisela ehlukahlukene kanye nemishini enobuchwepheshe bokulawula izinombolo ukuze ithuthukise izinga layo lokuguquguquka;

⇲ Inhlanganisela yerobhothi elishiselayo nohlelo lochwepheshe lubona imisebenzi efana nokuhlela umzila ozenzakalelayo, ukulungisa okuzenzakalelayo komzila, nokulawula ukungena okuzenzakalelayo;

⇲ Thuthukisa ukuthembeka, ukuzinza kwekhwalithi nokulawula umthombo wamandla wokushisela, kanye namandla amahle kakhulu. Thuthukisa futhi uthuthukise imishini yokushisela esebenza kahle kakhulu engalungisa ukunyakaza kwe-arc, ukondla izintambo nokuma kwesibhamu sokushisela, ibone ukuqala komthambeka we-weld, inkambu yokushisa, isimo sechibi elincibilikisiwe, kanye nokungena, futhi inikeze imingcele yokucaciswa kokushisela ngesikhathi esifanele, futhi ithuthukise ngenkuthalo ikhompiyutha yenqubo yokushisela. Ubuchwepheshe bokulingisa benza ubuchwepheshe bokushisela buguquke busuka “kumakhono” buyiswe “kwisayensi”.