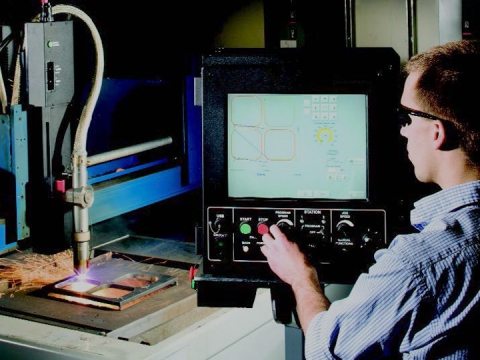

Iyini i-CNC Plasma Cutter futhi Isebenza Kanjani?

Ukuhlanganiswa kwe umsiki we-plasma futhi isilawuli se-CNC sibizwa ngokuthi umshini wokusika i-CNC plasma. I-CNC plasma cutter ihlanganisa isistimu ye-CNC elula nesebenziseka kalula ukuze i-ionize ukugeleza komoya okunesivinini esikhulu okukhishwa emlonyeni kumazinga okushisa aphezulu ukuze kwakhe amakhondatha kagesi. Lapho i-current idlula, i-conductor yenza i-arc ye-plasma ephezulu yokushisa, futhi ukushisa kwe-arc kubangela insimbi ekusikeni kwendawo yokusebenza ukuze inyibilike endaweni (futhi ihwamuke), futhi insimbi encibilikisiwe isuswa ngamandla okugeleza komoya we-plasma wesivinini esikhulu ukwenza indlela yokucubungula yokusika. I-arc ye-plasma emide futhi ezinzile eyakhiwe ubuchwepheshe bokugeleza kwegesi ye-annular iqinisekisa ukusika okubushelelezi nokonga kwanoma iyiphi insimbi eqhubayo.

Izinkinga nezixazululo

Enqubeni yokusebenzisa umshini wokusika i-plasma we-CNC, uzohlangabezana nokwehluleka okuhlukahlukene. Lapho ebhekene nezinkinga, opharetha kufanele 1st azole, ahlaziye izimbangela zokwehluleka kuhlanganiswe nezimpawu zezinkinga, futhi athole izixazululo zokuxazulula izinkinga.

Umfutho womoya osebenzayo uphansi kakhulu.

Uma i-plasma cutter isebenza, uma ukucindezela komoya okusebenzayo kuphansi kakhulu kunomfutho womoya odingwa yibhukwana, kusho ukuthi isivinini se-ejection ye-arc ye-plasma sibuthakathaka, futhi ukugeleza komoya okufakwayo kungaphansi kwenani elidingekayo. Ngalesi sikhathi, i-arc enamandla kakhulu, i-high-speed plasma arc ayikwazi ukwakhiwa. Ngenxa yalokho, ikhwalithi yokusikwa impofu, ukusika akungenwa, futhi ukusika kuyanqwabelana. Izizathu zokucindezela komoya okunganele yilezi: okokufaka komoya okunganele okuvela ku-compressor yomoya. Ukulawulwa kwengcindezi ye-valve elawula umoya yomsiki kuphansi kakhulu, kukhona ukungcoliswa kwamafutha ku-valve ye-solenoid, futhi indlela yomoya ayibushelelezi. Ngakho-ke, kuyadingeka ukuhlola kulezi zici ngamunye ngamunye, futhi uthole izinkinga futhi uzithuthukise ngesikhathi.

Umfutho womoya osebenzayo uphezulu kakhulu.

Uma ukucindezela komoya okokufaka kuphezulu kakhulu, ngemva kokwakhiwa kwe-arc ye-plasma, ukugeleza komoya okweqile kuzosusa ikholomu ye-arc egxilile, kuhlakaze amandla ekholomu ye-arc, futhi kwenze buthaka amandla okusika e-plasma arc. Izizathu eziyinhloko yilezi: ukulungiswa okungalungile komoya wokufakwayo, ukulungiswa ngokweqile kwe-valve yokunciphisa ingcindezi yokuhlunga umoya noma ukwehluleka kwe-valve yokunciphisa ingcindezi yokuhlunga.

Ukufakwa okungalungile kwezingxenye zokugqoka ezifana nama-nozzles e-electrode.

I-electrode nozzle intambo futhi idinga ukugoqwa endaweni. Ukufakwa okungalungile kwe-nozzle, njengentambo yesikulufu ayiqinisiwe, futhi indandatho yamanje ye-eddy ayifakwanga kahle, izobangela ukusika okungazinzile kanye nokulimala ezingxenyeni ezigqokile ngokushesha kakhulu.

I-voltage ye-AC yokufaka iphansi kakhulu.

Ngaphambi kokuthumela nokusebenzisa, hlola ukuthi igridi yamandla exhunywe emshinini wokusika i-plasma inomthamo owanele wokuthwala nokuthi ngabe imininingwane yentambo yamandla iyahlangabezana yini nezidingo. Indawo yokufaka umshini wokusika i-plasma kufanele ibe kude nemishini emikhulu kagesi kanye nezindawo ezinokuphazamiseka kagesi okuvamile.

Ukungaxhumani kahle phakathi kwentambo yaphansi kanye ne-workpiece.

I-Grounding iyilungiselelo elibalulekile ngaphambi kokusika. Uma lingekho ithuluzi elikhethekile lokumisa phansi elisetshenziswayo, kukhona ukufakwa ngaphakathi kwendawo yokusebenza, futhi ukusetshenziswa kwesikhathi eside kocingo oluphansi ngokuguga okukhulu kuzodala ukuthintana okungalungile phakathi kocingo lomhlabathi kanye nendawo yokusebenza.

Isivinini sokusika kanye nokuma kokubambelela kwethoshi.

Isivinini sokusika kufanele sisheshe noma sihambe kancane, ngokuya ngezinto ezahlukahlukene nobukhulu, futhi usayizi wamanje kufanele uhambisane. Ukushesha kakhulu noma ukunensa kakhulu kuzodala indawo yokusika engalingani kanye ne-slag emaphethelweni angaphezulu naphansi. Ngaphezu kwalokho, ithoshi yokusika ayibanjwa ngokuqondile, futhi i-arc ye-plasma efafaziwe nayo ifafazwe ngokukhululekile, okuzokwenza futhi indawo yokusika ibe nomthambeka.

Ukuxazulula

| Izinkinga | Imbangela Yodaba | Solutions |

| Vula umsingathi "ukushintsha amandla", isibani samandla asikhanyi | 1. "Isikhombi Samandla" ukukhanya kwephukile | buyisela |

| 2. I-2A Fuse yimbi | buyisela | |

| 3. akukho okokufaka 3-isigaba 380V voltage | Ukuqedwa | |

| 4. okokufaka 380V 3-isigaba ukulahleka kwamandla kagesi. "Ukuntuleka kwesikhombisi sesigaba" ukukhanya | Sebenzisa i-multimeter ukukala i-voltage yesigaba esi-3 kufanele ihlangabezane nezidingo | |

| 5. amandla nokunye | buyisela | |

| 6. iphaneli yokulawula embi noma umsingathi | Ukuqedwa | |

| Ngemuva kokuthi amandla okufakwayo esigaba esingu-3 evuliwe, isiphephetha-moya asivuli, kodwa ukukhanya kwe-"Power Indicator" kuyakhanya. | 1. okokufaka 3-isigaba amandla isigaba ukulahlekelwa | Impahla yokwakha isondela ngethebula 1.4 |

| 2. isiphephetha-moya sishiya sibhajwe yimizimba yangaphandle | Susa umzimba wangaphandle | |

| 3. ipulaki yamandla efeni iyaxega | Faka kabusha | |

| 4. Ukuhamba kwabalandeli | Ukuqedwa | |

| 5. ifeni yonakele | Faka esikhundleni noma lungisa kabusha | |

| Vula amandla okufaka ezigaba ezi-3, ukukhanya kwenkomba yamandla, ukuzungezisa abalandeli kuyinto evamile, kodwa vula iswishi "yegesi yokuhlola", umlomo wethoshi ngaphandle kokugeleza komoya. | 1. awukho umoya ocindezelwe okokufaka | Ukugcinwa kwegesi kanye nepayipi legesi |

| 2. umsingathi ubuyisela emuva "isilawuli sengcindezi yokuhlunga umoya" ukungalingani, igeji yengcindezi ikhombisa uziro. I-"Underpressure" ikhombisa ukukhanya okubomvu | Lungisa kabusha ingcindezi. Indlela: jikisa ngokwewashi "i-air filter pressure reducer" isondo lesandla ukuze ukhuphule, kungenjalo unciphise. | |

| 3. "igesi yokuhlola" ukukhanya okubi | buyisela | |

| 4. i-valve ye-electromagnetic host imbi | Shintsha kabusha noma shintsha | |

| 5. ukuvuza kwepayipi legesi noma isifunda esifushane | Ukuqedwa | |

| Vula iswishi "yegesi yokuhlola", umlomo wombhobho unokugeleza komoya, lapho kuvalwa isibani "sokusika", kuvala iswishi yethoshi, kodwa akubanga ijethi yomoya noma isenzo sohlelo lomsingathi. | 1. inkinobho yethoshi ephukile noma ephukile umugqa wokushintsha | Faka esikhundleni noma lungisa kabusha |

| 2. Iswishi "yokusika" ayilungile | buyisela | |

| 3. Umonakalo webhodi lesifunda somsingathi | Ukuqedwa | |

| 4. isiguquli esilawula umsingathi noma imigqa ehlobene noma izingxenye ezilimele | Ukuqedwa | |

| 5. umsingathi ngenxa yokuntuleka kwengcindezi phezu kwezinga lokushisa nezinye izizathu ngesikhathi sokuphumula sokuvikela | Kuze kube yilapho umfutho womoya ubuyela kokujwayelekile noma izinga lokushisa lomsingathi libuyela kokujwayelekile ngemva kokubuyela kwawo kokujwayelekile | |

| 6. Ithoshi lokusika elipholile ngamanzi elifakwe uhlelo lokupholisa amanzi alisebenzi kahle, noma ukuntuleka kwamanzi ethangini, okubangela ukuntuleka kokucindezela, ukuze umsingathi abe sesimweni esivikelekile. | Hlola futhi uxazulule, uma uMnyango Wokuhlinzeka ngamanzi kampompi umfutho, umfutho wamanzi kufanele unyuswe | |

| Vula iswishi yethoshi ngokugeleza komoya kubhobho kodwa ungasikiwe "phezulu" noma "phezulu". | 1. okokufaka 3-isigaba amandla isigaba ukulahlekelwa | Ukuqedwa |

| 2. umfutho womoya ungaphansi kuka-0.45Mpa | Lungisa kokujwayelekile ngendlela echazwe kuThebula 3.2 | |

| 3. ukugeleza komoya okokufaka kuncane kakhulu | Khulisa ukugeleza komoya okokufaka 300L / min | |

| 4. "sika umhlabathi" i-chuck kanye ne-workpiece engalungile ekuqhubekiseni kahle noma "i-cut ground wire" ukuphuka kwentambo | I-clamp noma i-conductor yesevisi futhi | |

| 5. ukusika ithoshi nozzle electrode noma ezinye izingxenye ezilimele | Ukushintshwa kwezingxenye ezintsha | |

| 6. indlela yokusika ayilungile | Umbhobho wethoshi kufanele ubekwe lapho kuqalwa khona umsebenzi wokusika ngaphambi kokuvula iswishi yethoshi | |

| 7. ikhebula lethoshi lokusika isifunda esivulekile | Sebenzisa ifayela le-multimeter R * 10 ukukala indlela ephakathi kwengxenye ye-conductive ye-host "interface yokuphumayo" kanye ne-electrode yethoshi, ngaphandle kwalokho ikhebula elingaphezulu liphukile. | |

| 8. Umsingathi "FD" igebe lenhlansi likhulu kakhulu noma elifushane | Lungisa kabusha igebe lenduku ye-tungsten seliseduze 0.5mm-0.8mm, uma uMnyango wesakhiwo senduku ye-tungsten, izikhala ezi-2 zengeza ngokulingana ne 0.5mm-0.8mm | |

| 9. ingxenye yomsingathi yolayini noma umonakalo wengxenye, njengesilawuli sokucindezela | Ukuqedwa | |

| 10, iziyaluyalu ibhodi control host noma umonakalo | Shintsha kabusha noma shintsha | |

| 11. umonakalo wethoshi | Sebenzisa i-multimeter R * 10K ifayela lokusika ithoshi isibambi se-electrode kanye nentambo yangaphandle engu-M32 noma inani lokumelana le-M35 kufanele lisondele ku-∽ kumakhulu we-K, uma ukumelana kukuncane kakhulu (njengama-Ka ambalwa Ω) kubonisa umonakalo noma umswakama, kufanele Ngemva kokuwasha nokomisa izilinganiso, ukuqinisekisa ukuthi umonakalo kufanele ushintshwe. | |

| Othintana naye angasikwa, kodwa okungeyena othintana naye akanakunqunywa, umbhobho wokuhlola ongadluliseli we-arc | 1.15A i-fuse fuse evulekile isifunda | buyisela |

| 2. "Isinciphisi somfutho wokuhlunga umoya" sibonisa inani liphezulu kakhulu | Lungisa ngendlela evezwe kuThebula 3.2 | |

| 3. Imbobo yethoshi ye-electrode noma ezinye izingxenye ezilimele | buyisela | |

| 4. ukusika ithoshi limanzi, umswakama womoya ocindezelwe mkhulu kakhulu | Ithoshi lomisiwe futhi umoya ocindezelwe uyomiswa bese ungena emshinini | |

| 5. "i-pilot arc interface" ukusika intambo phakathi kwethoshi uvule | Sebenzisa ifayela le-multimeter R * 10 ukukala "i-pilot arc interface" kanye nethoshi lensimbi lokusika kufanele lidlule. | |

| 6. ukusika umonakalo wethoshi | Indlela yokuhlola iyafana naleli thebula 5.11 | |

| Iswishi yokukhetha ukujiya kokusika ebekwe efayelini ingasikwa, kodwa elinye ifayela alisebenzi | 1. Sika inkinobho ewugqinsi noma ukukhetha kocingo kubi | buyisela |

| 2. omunye wabasingathi be-AC contactor CJ1 noma CJ2 embi | Faka esikhundleni noma lungisa | |

| 3. i-rectifier main transformer B1 embi noma ehlobene nesekhethi evulekile yocingo | service | |

| I-arc kagesi ayizinzile emsebenzini | 1. ingcindezi iphansi kakhulu noma iphezulu kakhulu | Ukulungiswa kabusha, indlela bheka ithebula 3.2 |

| 2. ukusika umlomo wethoshi noma ukushiswa kwe-electrode | buyisela | |

| 3. I-voltage ye-AC yokufaka iphansi kakhulu | Lungisa i-voltage ye-AC yokufaka | |

| 4. "sika umhlabathi" nomsebenzi ompofu phakathi kwe-conductive | Ixhumeke kahle | |

| 5. ukusika ezihamba kancane | Lungisa isivinini sokunyakaza | |

| 6. i-spark generator ayikwazi ukuphuka ngokuzenzakalelayo i-arc | Normal, vula ithoshi switch inhlansi generator isikhathi sokukhipha kufanele kube 0.5-1S, bese ayeke ngokuzenzakalelayo, ngaphandle kwalokho, ukuthi ukulawula ukuphazamiseka ibhodi wesifunda; ukulawula umjikelezo noma ukwehluleka kwengxenye, kufanele kulungiswe kabusha | |

| 7. izingxenye ezifanele kumsingathi azisebenzi kahle | Ukuqedwa | |

| Ukuqina kokusika kwe-Plasma kuze kufike ezinkomba ezilinganiselwe | 1. faka i-voltage ye-3-phase kufika ku-380V | Lungisa i-voltage yokufaka |

| 2. amandla okufaka amandla amancane kakhulu ukucindezela kokusika kwehle kakhulu | Kufanele yenyuse umthamo wokufaka | |

| 3. faka umfutho womoya ocindezelwe uphansi kakhulu noma uphezulu kakhulu | Lungisa ku-0.4Mpa, indlela bheka Ithebula 3.2 | |

| 4. faka ukugeleza komoya ocindezelwe kukuncane kakhulu, igeji yengcindezi yomsebenzi ikhombisa inani lehle lisuka kokujwayelekile liye cishe ku-0.3Mpa, yeka ukusebenza vala iswishi yamandla, ingcindezi ibuyele kokujwayelekile ngokushesha. | Kanye nokugeleza komoya okucindezelwe okokufaka ku-300L / min; uma uhlelo lusekelwe emgodini wepayipi lincane kakhulu, kufanele libe likhulu kuno-φ8mm wabhoboza imbobo epayipini | |

| 5. "Ukukhetha ukujiya kokusika" shintsha igiya elikhethiwe ngokungafanele | Shintshela ku-"upscale" | |

| 6. ukusika isivinini ngokushesha kakhulu | Yehlisa isivinini sokusika | |

| 7. izinto zokusebenza azihambelani neThebula lesi-2 | Imingcele yokulungisa | |

| 8. umgodi wombhobho ushisiwe | Lungisa umlomo wombhobho omusha | |

| 9. i-electrode ishile | buyisela | |

| 10. imodeli ye-nozzle ayilungile | Lungisa uhlobo olulungile lombhobho | |

| 11. isistimu yomoya noma ukuvuza kokulimala kwentambo yethoshi, bese ukugeleza kwe-nozzle orifice kwehliswe kakhulu | Lungisa noma shintsha | |

| Sika ukuchema kwezinto ezibonakalayo | 1. i-electrode ye-nozzle ilimele | buyisela |

| 2. i-nozzle electrode mounting isikhundla i-eksisi ehlukile | Faka kabusha kahle | |

| 3. ukusika ngokushesha kakhulu | Ijubane elifanele | |

| 4. i-axis ye-nozzle kanye nendiza ye-workpiece ayimi mpo | Lungisa futhi uxazulule | |

| Ukusika banzi kakhulu, izinga eliphansi lokusika | 1. isivinini sokusika sihamba kancane kakhulu | Lungisa ijubane |

| 2. umbhobho, i-electrode ishile | Kubuyekeziwe | |

| 3. Impahla yokusebenza, ukujiya kanye "nokusika ukukhetha okukhulu" isikhundla sokushintsha akufani | Ukulungiswa | |

| 4. imodeli ye-nozzle ayilungile, imbobo inkulu kakhulu | Faka esikhundleni uhlobo olulungile lombhobho | |

| Ithoshi lokusika i-Plasma lishile | 1. isivalo sensimbi asicindezelwe | Ngokuvamile buyisela i-nozzle ye-electrode kufanele icindezelwe ngokushesha |

| 2. ukusika amajoyinti ethoshi axegayo, intambo yoqhoqhoqho ephukile, ukuvuza kwesixhumi esibonakalayo sethoshi elipholile | Hlola futhi uxazulule ngesikhathi | |

| 3. ukusika amalunga ethoshi ukungagxili kahle | Kufanele siqinisekise ukuthi ukwahlukanisa at the okuhlangana okuhle | |

| 4. ithoshi yokusika ikhava yokuzivikela yobumba yonakele, kodwa ayishintshwa ngokushesha | Kufanele ishintshwe ngokushesha | |

| 5. umoya ocindezelwe emanzini amaningi | Ukukhipha okufika ngesikhathi "i-air filter pressure reducer" emanzini, uma kunomswakama womoya ocindezelweyo | |

| 6. ukusika ibhuthi, ukusika imodeli yethoshi engalungile | Ukusika okuhambisanayo kufanele kukhethe ithoshi lokusika elipholile ngamanzi, umthamo othwele ithoshi lokusika elipholile mncane kakhulu, awukwazi ukusetshenziswa. | |

| 7. i-electrode ayishintshwa ngemva kokushiswa | Ukushiswa kwe-Electrode kufanele kubuyekezwe ngokushesha | |

| 8. Ithoshi epholile amanzi esebenza uhlelo lwamanzi aluvamile noma izinga lokushisa le-ambient liphansi kakhulu, ukuvuza kwesixhumi esibonakalayo | Hlola futhi uxazulule, futhi awukwazi ukusebenza endaweni yezinga lokushisa eliqandayo | |

| Ama-diode okulungisa kabusha i-D1-D6 avame ukusha | 1. I-voltage entsha ye-diode reverse reverse iphansi kakhulu | I-Reverse voltage ukumelana> 1200V diode kufanele ikhethwe |

| 2. C101-C103; C104; C106 noma R101; U-R102 kokukodwa noma ezimbalwa ezilimele | buyisela | |

| 3. i-rectifier transformer B1 yonakele | Faka esikhundleni noma lungisa | |

| 4. Ithoshi lokusika i-Plasma lonakele | Susa ithoshi kuyunithi eyinhloko, nge-multimeter R * 10K ifayela lokulinganisa i-electrode kanye nethoshi yangaphandle intambo M32 noma M35. inani lokumelana kufanele lisondele ku-∽, uma lingaphansi kwamashumi ka-K, lonakele |

Ukuqapha

Uma usebenzisa i-CNC plasma cutter, ikhwalithi yokusika ayizinzile, futhi izingxenye zokugqoka zishintshwa njalo. Kutholakala ukuthi ukusebenza komsebenzisi akulinganiselwe ngokwanele ngesikhathi sokusebenza, futhi ngesikhathi esifanayo, akanaki ngokwanele eminye imininingwane. Kufingqiwe amathiphu athile okusetshenziswa kwansuku zonke kwemishini yokusika i-plasma ye-CNC, ngethemba lokukulethela lula:

Ukusika kufanele kuqale kusuka onqenqemeni.

Uma kungenzeka, qala ukusika kusukela onqenqemeni, kunokuba ubhoboze ukusikwa. Ukusebenzisa unqenqema njengendawo yokuqala kuzokwandisa impilo yezinto ezidliwayo, indlela efanele ukukhomba umlomo wombhobho ngokuqondile emaphethelweni omsebenzi ngaphambi kokuqala i-arc ye-plasma.

Yehlisa isikhathi "sokwenza i-arcing (noma ukushayela)" esingadingekile.

Kokubili i-nozzle kanye ne-electrode kudliwa ngokushesha okukhulu lapho kuqalwa i-arc, futhi ithoshi kufanele libekwe phakathi nebanga lokuhamba lensimbi yokusika ngaphambi kokuqala.

Ungalayishi kakhulu umlomo wombhobho.

Ukulayisha ngokweqile i-nozzle (okungukuthi, ukweqa umthamo osebenzayo we-nozzle) kuzobangela ukuthi umbhobho wehluleke ngokushesha. Ukuqina kwamanje kufanele kube ngu-95% wamanje osebenzayo we-nozzle. Isibonelo: i-amperage yenozzle engu-100A kufanele isethelwe ku-95A.

Sebenzisa ibanga elifanelekile lokusika.

Ngokwezidingo zemanuwali yeziqondiso, kwamukelwa ibanga elifanelekile lokusika. Ibanga lokusika liyibanga phakathi kwe-nozzle yokusika kanye nobuso be-workpiece. Uma ubhoboza, zama ukusebenzisa ibanga eliphindwe kabili kunebanga elijwayelekile lokusika noma ubuningi obungu-h8 obungadluliswa yi-plasma arc.

Ubukhulu bokubhoboza kufanele bube phakathi kwebanga elivumelekile lesistimu yomshini.

Umshini wokusika awukwazi ukubhoboza ipuleti lensimbi elidlula ubukhulu bokusebenza. Ugqinsi olujwayelekile lokubhoboza 1/2 yobukhulu obujwayelekile bokusika. Zama ukugcina ithoshi nezinto ezidlekayo zihlanzekile. Noma yikuphi ukungcola kwethoshi nezinto ezisetshenziswayo kuzothinta kakhulu umsebenzi we-plasma wesistimu. Lapho ushintsha izinto ezisetshenziswayo, zibeke kuflaneli ehlanzekile, hlola ubambo lokuxhuma lwethoshi njalo, bese uhlanza indawo ethinta i-electrode kanye nombhobho ngesihlanzi esisekelwe kwi-hydrogen peroxide.