Uzohlangana namathuluzi okusika ingilazi angu-3 avame kakhulu ukwenza izingxenye zengilazi ezenzelwe umuntu siqu kanye nezinsiza, okuhlanganisa i-Glasschneider, Umshini we-CNC, i-laser cutter, isiphi esingcono kubenzi bamaselula nezitolo zokulungisa ukusika ingilazi ye-smartphone njengengilazi ye-Gorilla, i-Sapphire, i-Dragontrail ingilazi yokwenza izikrini zeselula zeselula, izibonisi, izembozo zangaphambili, amaphaneli angemuva, ikhava yekhamera, isihlungi, ishidi lokuhlonza izigxivizo zeminwe, i-prism? Lesi sihloko sibala futhi siqhathanise okuhle nokubi kwabangu-3 abahlukene abasiki bengilazi ukukusiza ukuthi unqume ukuthi iyiphi ongayithenga futhi usebenzise.

Ukuvela kwama-smart phones kuzishintshe kakhulu izindlela zokuphila zabantu, futhi ukuthuthukiswa okuqhubekayo kwamazinga okuphila kwabantu kuye kwabeka izidingo eziphakeme zamafoni ahlakaniphile. Ukwengeza ekuthuthukisweni okuqhubekayo kwesistimu, i-hardware nokunye ukucushwa okusebenzayo, ukubukeka kwamaselula nakho sekugxilwe emqhudelwaneni phakathi kwabakhiqizi bamaselula. Enqubweni emisha yezinto zokubukeka, izinto zengilazi zamukelwa abenzi ngenxa yezinzuzo zabo ezifana nokubunjwa okuguquguqukayo, ukumelana nomthelela omuhle, nezindleko ezilawulekayo, futhi sekusetshenziswe kabanzi kakhulu ekukhiqizeni omakhalekhukhwini.

Nakuba impahla yengilazi inezinzuzo eziningi, ubuthakathaka bayo buletha ubunzima obuningi enqubweni yokucubungula, njengokuqhekeka kanye nemiphetho enzima. Ngaphezu kwalokho, ukusika okumise okukhethekile kwe-earpiece, ikhamera yangaphambili, ishidi lezigxivizo zeminwe nakho kubeka phambili izidingo eziphakeme kubuchwepheshe bokucubungula. Indlela yokuxazulula izinkinga zokucubungula izinto zengilazi nokuthuthukisa isivuno somkhiqizo isibe umgomo ovamile embonini yeselula yeselula, futhi sekuseduze ukukhuthaza ukusungulwa kobuchwepheshe bokusika ingilazi.

Okubalwe ngezansi ukuqhathanisa okuningiliziwe kwezinhlobo ezi-3 ezivame kakhulu zokusika ingilazi ezisetshenziselwa ama-smartphones angokwezifiso, amaphilisi namakhompyutha aphathekayo.

I-Handheld Glasschneider & CNC Glass Cutter

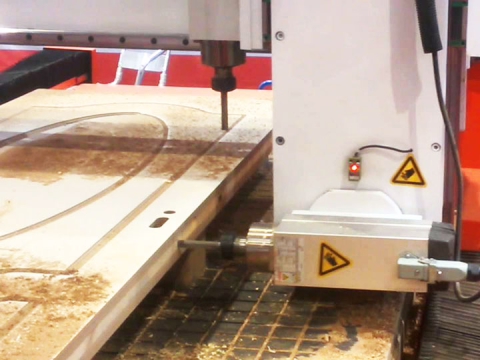

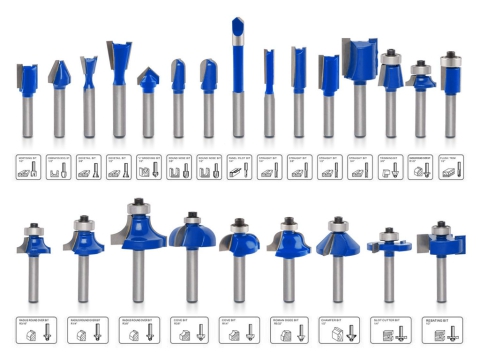

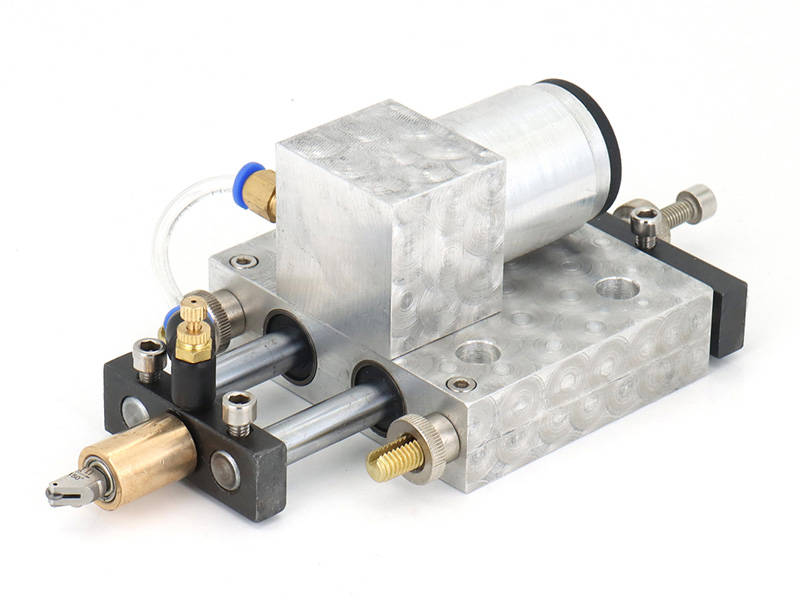

Amathuluzi okusika ingilazi endabuko afaka i-Glasschneider ne-CNC cutter. Ingilazi esikwe yi-Glasschneider inamaphethelo amakhulu ama-chipping namaholoholo, okuzothinta kakhulu amandla engilazi. Ngaphezu kwalokho, izinga lokukhiqiza lengilazi elisikwe yi-Glasschneider liphansi, futhi izinga lokusebenzisa impahla liphansi. Ngemuva kokusika, ukucubungula ngemuva kwezinqubo eziyinkimbinkimbi kuyadingeka. Isivinini nokunemba kuzoncishiswa kakhulu lapho i-Glasschneider yenza ukusika okumise okukhethekile. Ezinye izikrini ezigcwele ezinomumo okhethekile azikwazi ukusikwa yi-Glasschneider ngoba ikhona lincane kakhulu. Ukunemba kokusika kwe-CNC kungaphezulu kwalokho kwe-Glasschneider, ukunemba kungu-≤30μm, futhi ukuchopha komphetho kucishe kube ngu-40μm, kuncane kunaleyo ye-Glasschneider. Ububi ukuthi ijubane lihamba kancane.

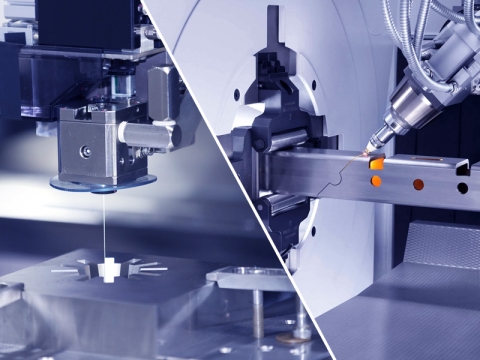

I-Ordinary Laser Glass Cutter

Ngokuthuthuka kobuchwepheshe be-laser, i-laser iphinde yavela ekusikeni kwengilazi. Ijubane lokusika ingilazi ye-laser liyashesha, ukunemba kuphezulu, ukusika akunazimbotshana futhi akunqunyelwe ukuma, futhi ukusika komphetho ngokuvamile kungaphansi kuka-80 μm.

Ukusika ingilazi ye-laser evamile kusekelwe kumshini wokukhipha umoya. I-laser egxilile enamandla amakhulu isetshenziselwa ukuncibilikisa noma ukufaka umoya ingilazi, futhi igesi elisizayo elinomfutho ophezulu liphephula i-slag esele. Ngenxa yokuthi ingilazi intekenteke, amabala okukhanya okugqagqana okuphezulu azoqongelela ukushisa okudlulele engilazini futhi aqhekeze ingilazi. Ngakho-ke, i-laser ayikwazi ukusebenzisa amabala okukhanya okugqagqana okuphezulu ukusika isikhathi esisodwa. Ngokuvamile, isibuko esidlidlizayo sisetshenziselwa ukuskena ngesivinini esikhulu ukusika ungqimba lwengilazi ngongqimba. Ngaphezu kwalokho, isivinini sokusika esijwayelekile singaphansi 1mm/ s.

I-Ultrafast Laser Glass Cutting Machine

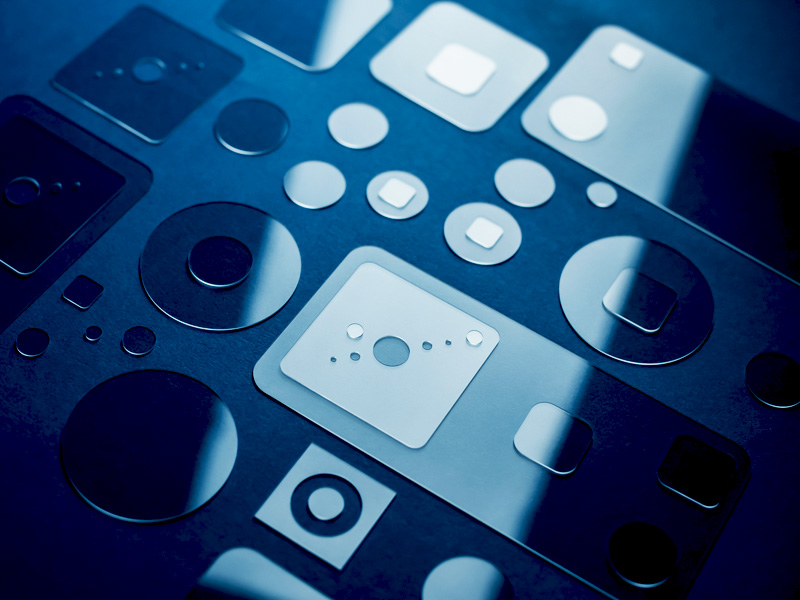

Eminyakeni yamuva nje, ama-lasers e-ultrafast (noma ama-laser we-ultrashort pulse) azuze ukuthuthukiswa okusheshayo, ikakhulukazi ekusetshenzisweni kokusika ingilazi. Iphezulu, ayikho imifantu emincane, ephukile noma izingcezu, ukumelana nokuqhekeka onqenqemeni oluphezulu, asikho isidingo sezindleko zokukhiqiza zesibili ezifana nokugeza, ukugaya, ukupholisha, ukunciphisa izindleko nokuthuthukisa kakhulu isivuno se-workpiece nokusebenza kahle kokucubungula. STYLECNCUmshini wokusika we-laser oshesha kakhulu unokusebenza okuhle kakhulu ekucubunguleni izinto eziphukayo. Ingakwazi ukusika izinto ezi-brittle kangcono futhi ngokushesha, futhi inciphise izindleko. Ngesikhathi esifanayo, i-laser izinzile futhi ingasekela izimo ezihlukahlukene.

Ingilazi eshesha kakhulu laser cutting system isebenzisa indlela yokucubungula yokumba i-galvanometer, ubukhulu bengilazi bungacutshungulwa kuze kube 1mm, ububanzi obuncane bembobo eyindilinga bungafinyelela ku-60μm, unqenqema olumnyama lungaphansi kuka-30μm, futhi ukusika kungaphansi kuka-10μm.

Umshini wokusika ingilazi we-laser oshesha kakhulu ungasekela ukubhoboza imbobo encane, ububanzi obuncane bembobo eyindilinga bungafinyelela ku-10 μm, kanti ukuchipha onqenqemeni kungaphansi kuka-5 μm. Ukusebenza kahle kokucubungula kuyashesha kakhulu, futhi kunezinzuzo ezingenakubuyiseleka ezimeni zohlelo lokusebenza ezifana nokubhola ingilazi ye-semiconductor kanye namashaneli amancane ezokwelapha.

Amandla we-laser asheshayo aqala ukusuka 10W, 20W, 30W, 50W, kuya ku 70W, futhi amandla aphezulu e-pulse eyodwa angafinyelela ku-1.5mJ, angahlangabezana neningi lezidingo zamakhasimende zamalaser e-infrared pico2nd.

Imvamisa yokusika isuka ku-10K-1000K, ukuzungeza kwendawo yokukhanya kungafinyelela ngaphezu kwalokho 90%, futhi ukuzinza kwe-pulse kungaphansi kuka-2%. Ingaqinisekisa ukuthi akukho ukuvuza kwe-pulse ngesikhathi sokucubungula, futhi usayizi wamachashazi uhlala unjalo. Kumodi yesitimela esishayelayo, amandla okushaya kwenhliziyo makhulu, futhi ukuqina kwe-sub-pulse eyodwa kungalungiswa ukuze kuhlangatshezwane nezidingo zenqubo ehlukene yamakhasimende.

I-Ultrafast laser inezinzuzo ezingenakuqhathaniswa ekusikeni izinto ezihlukahlukene ezibonisa ngale neziphukayo, njengengilazi, isafire, nesikrini esigcwele. Akukona nje kuphela ukusika ukushuba ububanzi ububanzi, kodwa futhi izinga cutting muhle, akukho Chipping, imfucumfucu, kulula ukwakha micro-imifantu, high ukugoba amandla, futhi ungakwazi ukufeza noma yikuphi ukusika ukuma ngaphandle taper (umugqa oqondile, ijika, imbobo round nezinye bobunjwa & contours).